Trim Story: On my way to

the

CopperState Fly In October of 2014, I was doing a high speed (for a

Cub) descent towards a landing in St Johns, AZ for a fuel stop. Trimmed

nose down, I noticed the stick alternately cycling fore and aft, then

suddenly something broke. I had a sudden high speed flutter in

the tail with the stick shaking hard fore and aft with the flutter.

I was still 12 miles out from St Johns. I slowed to Minimum

air speed and reduced to minimum power. Neither seemed to help.

I was about to set the plane down in the dirt 6 miles out from St

Johns when my passenger suggested I try pulling in flaps. The

flaps moderated the speed of the flutter, so it was a bit less violent.

At that point, I decided it would be safe to continue on into St

Johns to evaluate the situation and make repairs. Once on the

ground, I found that the single bowden cable used for trim control as

shown in the Wag Aero plans was pushing the trim tab up while trimmed

nose down. The aerodynamic load on the trim tab was causing the

bowden cable to bend back and forth. The fore and aft cycling I

had felt in the stick was the cable to the trim tab bending under load.

Then the cable broke, which was the impetus for the trim tab to

go into a high speed flutter. By the time I landed at St Johns,

about half of the pulled rivets holding the piano hinge mount for the

trim tab to the elevator had sheered. The good people at St

Johns managed to find me a drill and rivet puller, and helped me locate

a new cable and some pulled rivets at an auto parts store. (the

new cable was a remote throttle for a fire engine and cost a minor

fortune!) I was able to replace the cable and continue the trip,

but it was obvious to me that if I ever intend to trim nose down,

something had to be changed.

On my other plane, I had installed a Ray Allen trim servo in the

elevator. It is simple and very effective, so why not install the

same in the Sport Trainer. So I ordered a Ray Allen T2-10A kit

with an indicator, installation wire, and servo relay deck. I

ordered a

pair of stick grips from Chief Aircraft that came with the "chinaman

hat" trim switch as well as a PTT. I also ordered some 1/2"

square 4130 tubing to use to modify the elevator for mounting the trim

servo.

I removed the left elevator and stripped the fabric from the elevator

and trim tab. The Trim servo is slightly thicker than the

elevator, so I welded in the 1/2" tube to form the bottom of the

elevator a bit to make sufficient space to mount the trim servo.

I added a brace into the trim tab for mounting the control arm

and welded in a tab aligned

with the servo so the servo can actuate the trim tab. When I

recovered the elevator, I made a customized access panel the same size

as the trim servo using a piece of acetate with a cut out in the center

that matches the servo.

June 2015 - modifications made during Annual Condition Inspection.

Unfortunately, I didn't take photos while I did this work, so the

photos are only the finished product. However, I did a similar trim installation on my KR-2S a

couple of years earlier, which may make a good reference for this.

Servo mounted forward against the leading edge tube in the elevator.

The two 1/2" square tubes I added are rib stitched just behind

the servo.

There are two thin 4130 plates welded to the bottom of the 1/2" square

tubes with nut plates riveted into them for mounting the servo.

The

square ring around the servo was cut from acetate sheet, then covered

the same as any other access panel, then cut out after the covering was

completed. The control rod is a 10-32 threaded rod covered with

gray heat shrink.

Full nose up trim.

Full nose down trim.

I bought two of these stick heads from Chief Aircraft. They came

complete with the switches.

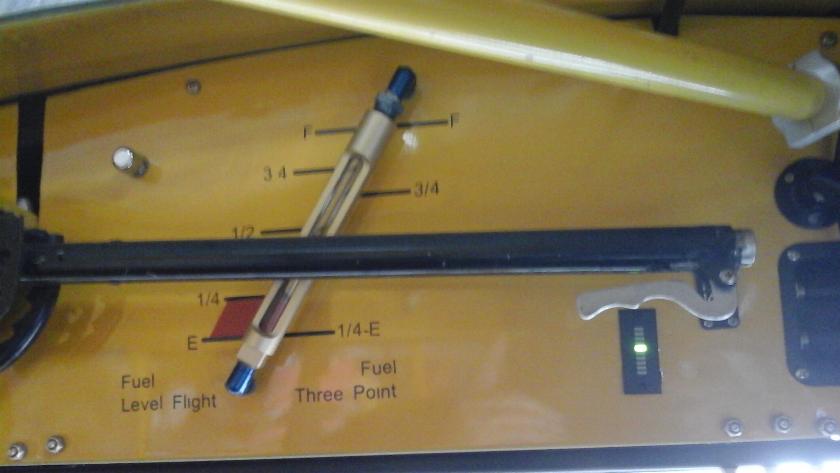

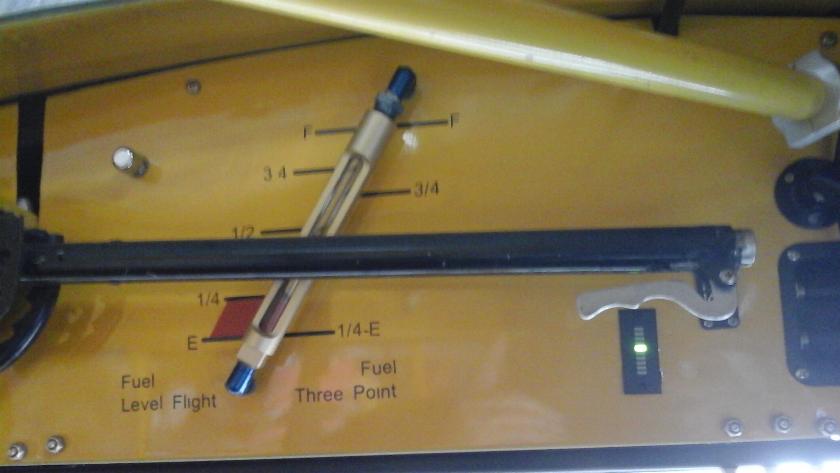

The LED that's illuminated is the trim indicator in the left wing root

just behind my flap handle. It's probably worth

noting that my switch setup required the Ray Allen Relay deck, which is

mounted behind this panel next to the trim

indicator.

Note the tiny double fabric patch in the center of this photo.

That's where the top of the trim servo rests against the bottom

of the fabric. The

servo is actually a bit thicker than the elevator.

Finished product. Note the wire that comes out of the fuselage

and goes through the fabric into the elevator. That's the wiring

to the trim servo.

Bungees vs Die Spring Gear

Nov 2015 - I've shredded yet another bungee cover. Yeah, I know.

I could have made a teardrop shaped metal can to house the

bungees.

But I preferred the look of the leather black bungee covers. But

they don't seem to last more than about 2 years. I was at a

hangar sale and

ran across a set of die spring struts for a Sport Trainer.

Offered $50, so now I have the die spring struts. I'll give

them a try.

Clearly the die spring struts are goint to be a lot less drag than the

bungees.

You can see that I had to do a bit of grinding to get these struts to

fit up between my fittings. Clearly I need to touch up the paint

a bit before

I call them finished.

Short of touching up the paint here's the finished product. I

don't know the spring rate for these springs, but I like the way they

feel. On the

other hand, I haven't pounded the plane on or landed off field yet.

I'm thinking a set of safety cables may be in order in case of

failure.

Seems a bit cleaner than the bungee installation here. Note the

brake installation in this photo as changing the brakes follows below.

2/22/16 - I bought a set of safety cables for the

gear. After having flown with the die spring struts on the

gear for a couple of months now, I have to say that I really like them.

My bungees were always really stiff, and perhaps were

too tight for my plane. But if you actually landed on them hard

enough for them to stretch a bit, they would snap back and

launch you. The die springs have a gradual spring rate to them,

which makes them soft and springy, so even off in the rough

the bumps aren't transmitted to the airframe so much. It also

makes soft landings really easy.

5/30/2016 - A photo of the safety cables. I also mounted a

set of GoodYear 26" smooth Blimp tires.

5/30/2016 - Also added hubcaps during the annual this year.

Brakes for Bushwheels

Nov 2015 - I bought a used set of 26" Good Year Blimp tires, typically

used as bush tires for planes that spend most of their time landing on

pavement and asphalt like I do. I haven't installed the tires

yet, but they came with a set of 40-60 Cleveland Wheels and

Brakes. One of the

wheels had significant corrosion, but cleaned up and is, in my

opinion, still airworthy. However, my SC clone has 1 1/2" axles

and the 40-60

wheels were made for 1 1/4" axles. They are typically

specified in most SuperCub bushwheel installations. I don't think

I really

need more

braking power since I have Matco master cylinders rather than the wimpy

Scott masters supplied by Piper in the real SuperCubs, but once I

looked at the 40-60 brakes, the reason they are

specified became obvious. They have roughly 1/4" offset in the

disks and torque plates to make

more room between the brake calipers and the

tire, which is really important when you stick a set of mushy balloon

tires on there. Additionally,

the brake calipers on my old 40-59D

wheels, while working well, are in less than ideal condition. So

I decided to see if I couldn't adapt the

40-60 brakes to fit my 40-59D wheels.

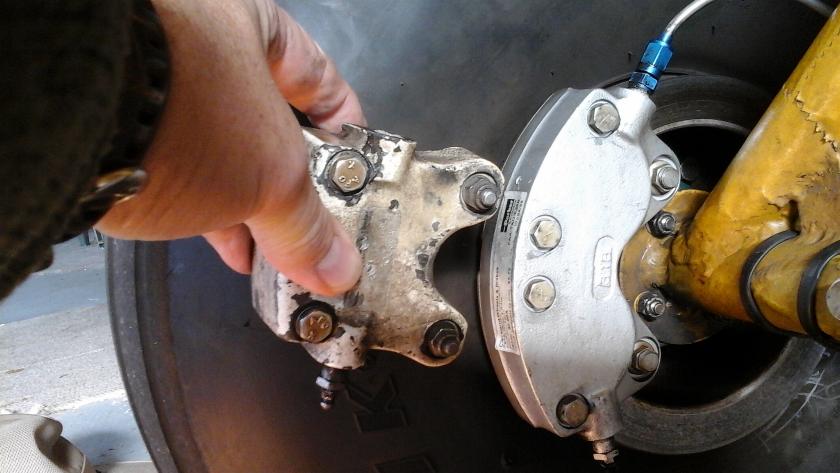

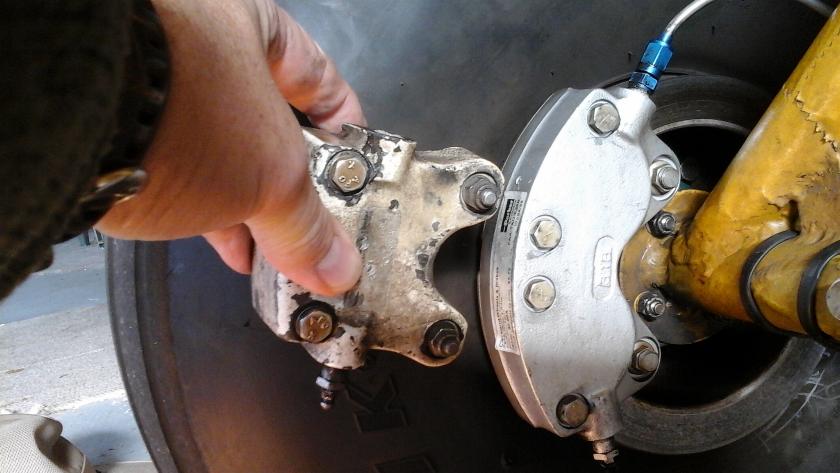

Here was the biggest problem. The 40-60 wheels use six 1/4"

bolts, while the 40-59D wheels use three 5/16" bolts. Also the

bolt pattern

has is about 1/8" tighter diameter, so I had to drill the 40-60 brake

discs to adapt to the 40-59D wheels. The discs did fit the wheels

and

center up properly, so the only issue was drilling the discs accurately.

Note the extra clearance between the tire and brake caliper with my

8:50/6 tires. That should

accommodate the fatter bushwheels when I'm ready

to mount them.

Note the difference between the double puck 40-60 brake calipers vs the

40-59D brake calipers. The extra braking power is kind of nice to

have, and I'm sure I'll appreciate it after I install the larger tires.

But the feel of the brakes with the double puck calipers actually

feels about the

same.

I now have a spare set of 40-60 Cleveland wheels with all new bearings,

races, felt seals, washers, and circlips. Additionally, I have a

set of

40-59D brake discs, calipers, and torque plates. Drop me a line

and make an offer. If one wants a set of Cleveland wheels for 1

1/2" axles,

I also have access to a new set of wheels discs that will work with the

40-59D brake calipers. They come complete with bearings,

seals, etc.

July, 2022 - Battle of the tailwheels. I have been battling with

a chronic tailwheel shimmy issue off and on with the Cub for 10 years

now. I replaced the original 3 leaf spring with a 4 leaf srping

from Univair and that seemed to help for a while. Then it was

back. I replaced it again, but every time I put any load in the

back seat, the tailwheel shimmy was back. I'm fed up with it.

I was wanting to move the Scott 3200 over to my biplane, so

ordered a new Matco 11D tailwheel. That's the 11" diameter wheel

with a 4" wide slick tire on it. Yeah, it's a go cart racing

slick, but it looks great on there. I installed it on the Cub and

move the Scott 3200 to the biplane. It shimmied like mad on the

biplane as well, so I switched it back to the Aviation Products 6"

tailwheel. The Matco tailwheel seemed to behave, right up until I

put a load in the back seat again. Dang. As big as that

tailwheel is, when it shimmies, it really hammers the tail. I

decided I have to put thi sproblem to bed. So, I took the spare 4

leaf tailspring and some simple wooden tooling I made up on the band

saw and bent a much more acute arc into the tailspring, one leaf at a

time. The tailwheel looks almost silly with so much caster in it,

but that seems to have addressed the issue. I need to put a load

in the back to know for sure. the Scott TW became a spare, so I

sold it to a friend for his Stinson project, although I probably should

have bent a new arc into the tailspring on the biplane and installed it

there.

Scott 3200 still mounted to the Cub.

New Matco 11D tailwheel. I like the looks, but still shimmies.

The upper spring is the 4 leaf spring in new condition from Univair.

The lower spring is the set I reformed in the press. This

appears to have killed the shimmy, but I need to test with a load in

the back seat to know for sure.

Page 1 - The Cub

Project

Page 2 - Fabric

Page

3

- Firewall Forward

Page

4 - Firewall Forward (page 2)

Page

5 - O-320

Overhaul (for the Cub)

Page 6 -

Final Assembly (2010)

Page

7 - Final Assembly (2011 page 2)

Page

8 - Final Assembly (2011 page 3)

Page 9 - Completed

Aircraft

Page

10 - Later Updates and

Modifications

Page 11 - MOGAS vs

Composite Fuel Tanks

POH

for Scott Grizzly Cub N143W

Feel free to email me at jscott.planes "at" gmail.com