Fabric Work

Page 1 - The Cub

Project

Page 2

- Fabric

Page

3

- Firewall Forward

Page

4 - Firewall Forward (page 2)

Page

5 - O-320

Overhaul (for the Cub)

Page 6 -

Final Assembly (2010)

Page

7 - Final Assembly (2011 page 2)

Page

8 - Final Assembly (2011 page 3)

Page 9 - Completed

Aircraft

Page 10 - Later Updates and

Modifications

Page 11 - MOGAS vs

Composite Fuel Tanks

POH

for Scott Grizzly Cub N143W

4/9/2010 - I pulled the wings off the plane today. Next time

they go back on will be to fly. I wasn't happy

with the slack that was in the sheet metal on the leading edge of the

left wing. I pulled most of it loose and mounted

it again.. I can't say that I'm really happy with it yet,

but it 's an improvement.

The leading edge is tacked back down to the ribs. It looks better

now, but isn't as tight as I wanted.

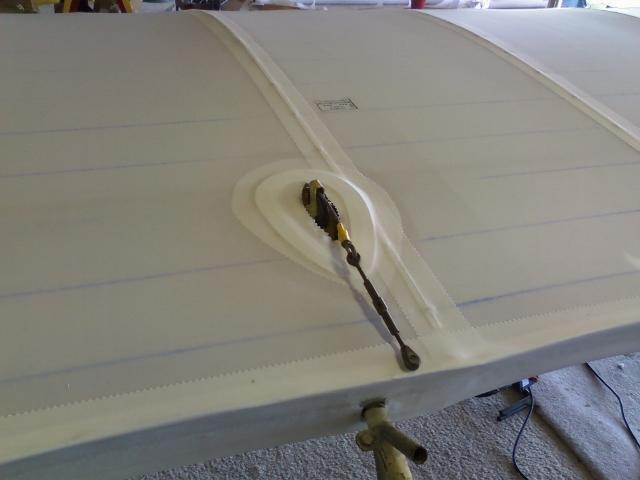

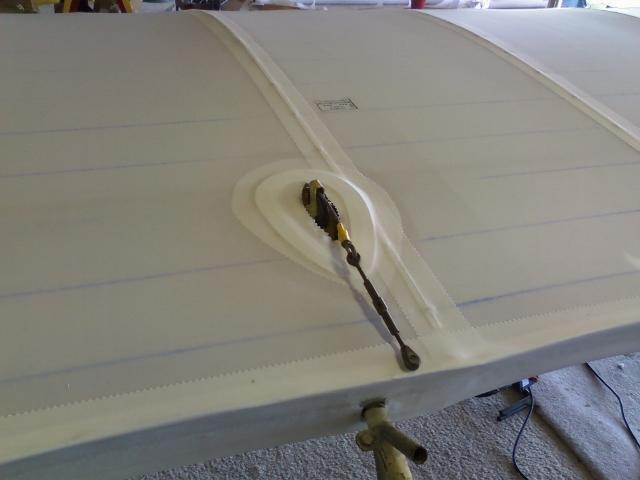

This photo shows the inter rib bracing for both wings. The

interrib bracing is the X configured lacing that runs

between the center of the ribs and is used to pull the ribs up straight

in preparation for the fabric. Once the

fabric is on and the rib

stitching completed, the bracing isn't really necessary.

The white tape you see on the tops of the ribs and covering all the

nails and rivets is simple athletic tape. It's

there to keep the fabric from abraiding on the sharp edges.

July 5, 2010. Finally getting rolling on the fabric work.

For future reference, here's the wing lay out. A little different

from most Cubs as the wings are squared off

instead of using wing tip bows and the ailerons have been moved 18"

outboard.

I've got the bottom of both wings covered and partially glued.

I need to shrink the leading edge to get rid of the

wrinkles before covering the top. So far, it's going well and

looking good.

Note how nice and straight the trailing edge is here.

Unfortunately, it wasn't tough enough and shrinking the fabric

really bent it creating a scaloping effect to the trailing edge.

July 11, 2010. More fabric work. I covered

the top of the wings and shrank all of the fabric. There is still

a

great deal more to do, but this is a good start.

July 17, 2010 - About an hour to relearn the Modified Seine Knot, then

an evening of stitching and a half day

on Saturday, and the wings are stitched. 3 1/2 inches per stitch

per the Ceconite STC. Yes, I did snap chalk

lines on the wing to guide the rib stitching. I'll wipe it down

with a damp cloth before I start spraying the dope.

The chalk won't disolve and migrate through the dope like ink, so it's

safe to use on the fabric.

The inboard ribs over the fuel tanks have an aluminum shell, so PK

screws were used to attach the fabric.

Inboard the fabric is attached at 2 1/2 inch intervals. Notice

the reinforcement tape on the top of the ribs. It

is a polyester tape that is under the PK screws and rib stitching to

keep the fabric from tearing if it happens

to lift up.

July 19, 2010 - This and the following few pictures show the

access panels and re-inforcements for the fabric

on the bottom and top of the left wing. The right wing is done

exactly the same.

Note: Notice the bending of the trailing edge in this picture. It

gets worse as the dopes taughten the fabric. I

did use non-taughtening dopes, but they will still cause some

taughtening of the fabric.

The three small screws in the inboard ribs are there to mount the clip

that holds the left window up against the

wing. There are three more screws in about the same position on

the right wing to mount the clip to hold the

upper door open as well.

Top aileron cable where it exits the wing. That's a plastic

re-inforcement under the patch for attaching the

blister fairing that covers this pulley and cable exit.

July 20, 2010 - Covered Gear legs.

July 24, 2010 - I was accused of having my laundry hanging from the

hangar door. Actually, the tail feathers

and gear legs are hung from the hangar door so I can shoot them with

dope.

July 25, 2010 - You can tell by the sheen on the wings that the wings

and controls have been sprayed with

butyrate dope. At this point, I have shot 5 coats of Nitrate and

5 coats of butyrate dope.

July 25, 2010, end of day. Just getting started with the silver

coat. After three 12 hour days in the hangar, all

of the fabric surfaces were shot with 3 coats of Nitrate dope, all the

tapes sanded, shot with 2 more coats of

nitrate, then 5 coats of clear butyrate dope. I just got started

with the silver butyrate, so shot everything except

the main surface of the wings. That's where I ran out of dope

that I had mixed, so will pick up there next time.

The surfaces all need to be sanded once more with 320 wet, then finish

shooting the silver coat. Then at last

I'll be ready for that Cub yellow paint.

Notice the scalloping that has developed along the trailing edge of the

wing in the photo above. The fabric pulls

with a great deal of force as it shrinks. The aluminum

trailing edge wasn't strong enough to hold against the force

of the shrinking fabric and dopes, which creates the scalloped effect.

It's not a structural problem, but will create

more of a gap between the control surfaces that mount here and the

trailing

edge of the wing than desired. Not much

to do about it at this time unless I want to go to the trouble to

create

some type of gap seal to close up the gap.

July 25, 2010 - Control surfaces are now all silver. More coats

of silver to go.

July 31, 2010 - Control surfaces after 5 coats of silver dope.

In person, these were

really shiny silver.

OK, all this silver is the culmination of two weeks or spraying.

5

coats of clear nitrate, 5 coats of clear butyrate,

and 5 coats of silver dope. So that's 2 hours spraying per coat,

so 30 hours with the spray gun in my hand.

Another way to look at it, is that I went through 4 1/2 gallons of

nitrate and 4 1/2 gallons of nitrate thinner.

Then I used 9 gallons of butyrate, 9 gallons of butyrate thinner, and 2

gallons of butyrate blush retarder. That

makes 29 gallons that I shot through my spray gun.... 1 pint at a time.

Yet another way to look at is is that

I burned through almost $2400 in covering supplies this month.

Whew! And now we get into the expensive

paint!

Aug 1, 2010 - Finally, I'm onto the color coat. I did the gear

legs first so I can get them back on the plane,

which will enable me to pull off the boot cowl for painting. I

really need my bungee tool which is on back order

from Wag Aero so I can put the bungees on the gear when I install them

this week.

The horizontal stabs.

I shot the bottom side of the flaps and ailerons. I'll flip them

over and paint the top sides sometime this week

when I mix paint again.

The wings have their finish coat of yellow completed. I normally

would have shot them with pigmented dope.

However, since when Roger shot the fuselage he used PolyUrethane paint

to get that nice wet look shiny finish,

I had the paint matched and also used PolyUrethane for the color coat.

I do have to say, it is very shiny.

Now these are nice shiny surfaces. Unfortunately, they weren't

done. After a close inspection, there was still

some silver showing through the yellow finish making it appear dark so

it didn't match the fuselage. I shot one

more coat and hosed it. I added some accelerator to the paint and

it started curing while I was shooting. Made

a real mess out of the paint. I cleaned it up as best I could,

then shot a 20th coat. (5 nitrate, 5 clear butyrate,

5 silver butyrate,

and 5 polyurethane color coat). Painting isn't easy and isn't a

lot of fun.

You can see the orange peel effect in the paint after shooting with

overcatalyzed paint.

Aug 7, 2010 - Finished wings (orange peel and all) after 20 coats.

Finished tail feathers.

I also shot the lift struts today.

Aug 15, 2010 - Painted the inspection covers, overhead trim panels,

windshield trim, landing light trim, wing

tips, sunroof. and a few other parts. At the end of the day, we

had quite a rainstorm blow up and had rain

blow in on the cowling top, and wing tips while the paint was wet, so

they will have to be wet sanded and shot

again.

Page 1 - The Cub

Project

Page 2

- Fabric

Page

3

- Firewall Forward

Page

4 - Firewall Forward (page 2)

Page

5 - O-320

Overhaul (for the Cub)

Page 6 -

Final Assembly (2010)

Page

7 - Final Assembly (2011 page 2)

Page

8 - Final Assembly (2011 page 3)

Page 9 - Completed

Aircraft

Page 10 - Later Updates and

Modifications

Page 11 - MOGAS vs

Composite Fuel Tanks

POH

for Scott Grizzly Cub N143W