The Cub project

Page 1 - The Cub

Project

Page 2 - Fabric

Page

3

- Firewall Forward

Page

4 - Firewall Forward (page 2)

Page

5 - O-320

Overhaul (for the Cub)

Page 6 -

Final Assembly (2010)

Page

7 - Final Assembly (2011 page 2)

Page

8 - Final Assembly (2011 page 3)

Page 9 - Completed

Aircraft

Page 10 - Later Updates and

Modifications

Page 11 - MOGAS vs

Composite Fuel Tanks

POH

for Scott Grizzly Cub N143W

Jan 15, 2010 - Scott Wilson getting ready to say good bye to

his

daddy's project. Scott's father Roger

started this Super Cub

project based on the Wag Aero Sport Trainer plans.

Unfortunately,

Roger passed

away before finishing his plane. I

acquired

this project from Roger's son Scott. We had just finished loading

it for the

move from Rutherford, TN to Los Alamos, NM.

1/17/10 Big truck and an empty hangar. Jeff must be

getting geared up for

another project. What better place

for the Cub project to

move to?

1/17/10 The Cub in it's new home. Yes, it

is living in a carpeted

hangar! The wings are leaning against the

back wall and one

of

those engines on the stands back behind it will eventually power it

power it into flight.

For now, I am assessing the condition

of

the project and trying to figure out where to start.

Update: I bought another engine to go on the Cub. An O-320-E2G

that I'll overhaul for it.

1/23/10 Rotating wing racks. These are configured

so the

wings can be rotated to any position. These should

come in

pretty

handy for covering the wings.

1/30/10 Installed aircraft landing lights into wings and pulled

aircraft grade wiring though the wings for landing

lights, tip lights, and strobes. Eventually changed to

AR 111/PAR 36 type LED lighting.

2/6/10. Today was assembly day. I really

needed to put the plane together so I could check the rigging of

the wings and so I can install and rig all the controls.

I also want to find any issues with the wing or control

surfaces before I cover the wings. Yesterday I reamed all of the

landing gear fittings and installed the gear

with the AN bolts. We also reamed all of the wing and lift strut

fittings to size in preparation for mounting

the wings. There was some misalignment of the wing attach

fittings, so the holes were aligned a bit better and

drilled and reamed from 5/16" to 3/8" .

As the day went on, I kept adding the control surfaces.

Boy, this plane has some wing span!

Tail feathers and control surfaces installed.

Wings from behind.

Side view.

Other side.

2/20/10 - I've been rebuilding the swing out windows. The right

window had a lot of heavy stuff on it that I

cut away, then bent some light weight aluminum to hold the windows onto

the frame. I wasn't happy with the

fit of the left side window, so built a new window frame. Here

you see the new window frame hooked to the

latch I built onto the wing today.

This is the rebuilt right side window and the wing latch. Note

that the hinges on both sides currently have Clecos

holding the hinges to the airframe. These will be replaced with

steel pulled rivets after I prime the hinges.

Update: I decided not to trust pulled rivets for this and used AN

grade #8 machine screws nutted on the inside to

hold the upper panels in place.

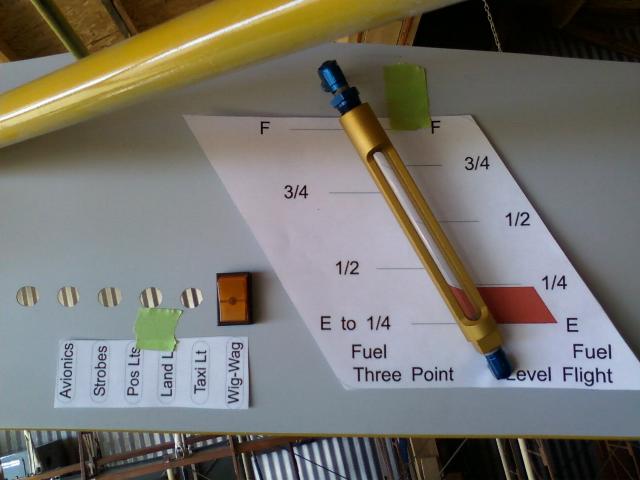

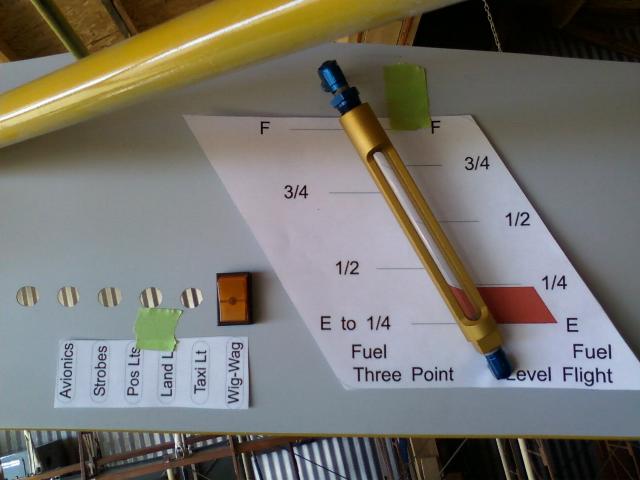

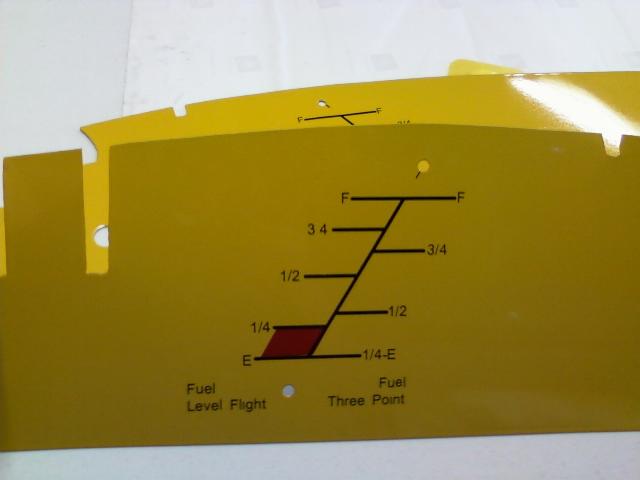

Design of the left overhead panel with the fuel sight gauge drawn in

just behind the flap handle. That other black knob

up there is the trim. Unlike the original Pipers, this plane has

a trim tab like a Champ rather than a trim jackscrew.

Right overhead panel with fuel sight gauge taped into place.

45 degrees of flaps. Now that's some serious flaps! These

wings are extended 18" on either side, so the

ailerons were moved outboard 18" and the flaps are 18" wider than a

normal SuperCub.

The left side window plexiglas still covered with the protective paper

finish for now.

Note the deficiency in the aft jury strut. Roger redesigned the

lift struts which made a slight change to the geometry

of the struts. The consequence is that the aft jury strut is just

a tad bit short. It's not a bit problem to fix. I bought

some streamlined 4130 strut material from Wicks and will measure the

correct length when the wings go back on,

then build a new jury strut to fit.

Second note: When I switched the jury struts around and

mounted

to front strut on the front and the back strut

on the back, everything fit much better.

Right side windows. Plexiglas covered with protective paper.

3/13/10 - The engine finishing kit arrived from Wag Aero

yesterday. As expected, it didn't quite fit. The right

bottom

mounting bracket was off by 3/16". I fabricated a new bracket and

added a couple of shims behind the upper left bracket

to get the mount to fit correctly. I figured I might as well see

if I can get the boot cowl fitted as long as I had the mount

to hold it in place.

As long as I was on a roll, I figured I might as well get the

windshield out of the box and see if I could get it fitted

as well. It all fit together very nicely.

I didn't capture a picture of it, but also checked the interface

between the windshield and the skylight. It was

also a very nice fit.

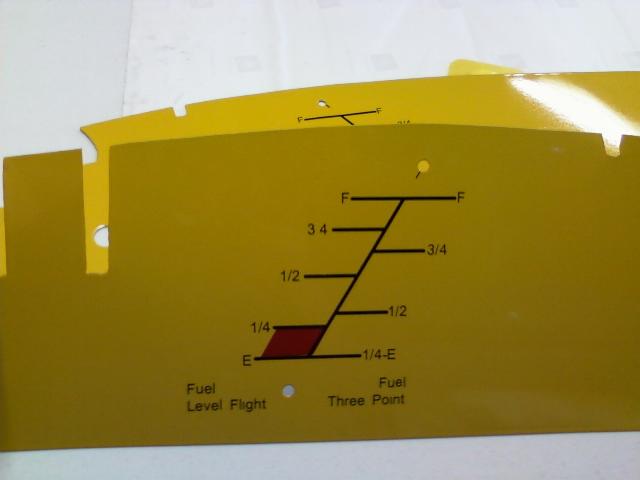

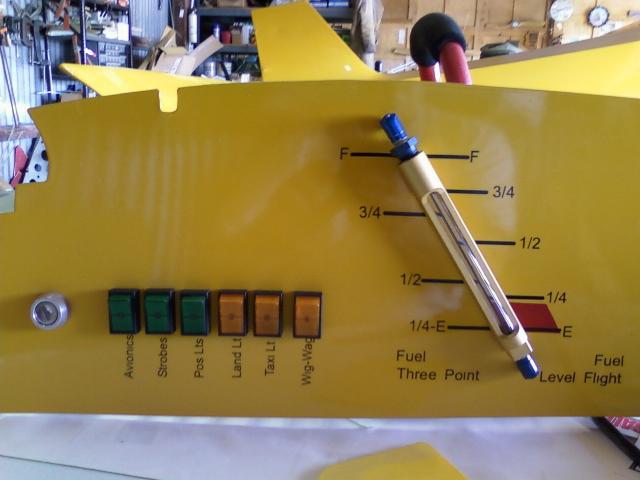

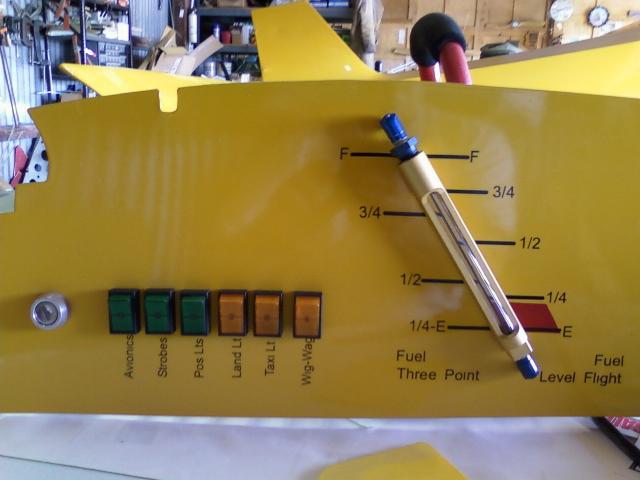

3/28/2010 - This is the overhead switch panel on the upper right side.

The hole behind the switches and the mark

above the swiches is where the fuel gauge goes throught the panel.

This is a long way from being done as it's

still covered with plastic. It will get an alodine treatment,

primer, painted yellow to match the plane, then vinyl

graphics for the switches. Why put the mags and switches in the

overhead area? I'm equipping this plane so it

can be flown solo from either seat. I've also found a radio with

a remote head so it can be controlled from either

seat. Xcom Radio. Nice unit.

Wiring Spaghetti. I'm installing the wiring for the lights

landing

lights, and strobes. It looks like a mess, but really

will clean up nicely.

More Spaghetti! Looking across at the left side. The two

square boxes hanging down are recessed plugs for the

headsets. The blue lines are the header tank vent return lines.

4/9/2010 - I pulled the wings off the plane today. Next time

they go back on will be to fly. I wasn't happy

with the slack that was in the sheet metal on the leading edge of the

left wing. I pulled most of it loose and

mounted it all over again..

The leading edge is tacked back down to the ribs. It looks better

now, but isn't as tight as I wanted.

Back panel and baggage sack.

Boot cowl in primer. Note that the glareshield area is now black.

Overhead panels and various pieces of the trim after priming and

painting the trim. The overhead panels

will end up getting painted yellow to match the plane.

More of the trim painted black.

4/26/2010 Fitting the graphics for the fuel gauges and overhead

switch panel.

Left side overhead panel with fuel gauge graphics.

Aug 29, 2010 - The real deal for the fuel gauge. Graphics

courtesy of Cameron at Ultra Industries. Right side

overhead panel with fuel gauge and switch panel.

And here's the engine. This is a Lycoming O-235-L2C (118 HP

@2800 RPM). It sat for a while before I

bought it and has some internal corrosion problems. I bought

this engine as a spare to rebuild for my Tomahawk,

but never needed to use it. I'll overhaul it and mount it

on the Cub. I may rebuild it as a high compression

O-235-L2C-M, which would make it 125 HP @ 2800 RPM. The upgrade

requires different pistons, different

spark plugs for clearancing reasons, and the addition of an oil cooler.

Note: I used this engine to fit up the cowling, but then ran across an

O-320-E2G that I'm now planning to use. More

on the Firewall Forward page.

Page 1 - The Cub

Project

Page 2 - Fabric

Page

3

- Firewall Forward

Page

4 - Firewall Forward (page 2)

Page

5 - O-320

Overhaul (for the Cub)

Page 6 -

Final Assembly (2010)

Page

7 - Final Assembly (2011 page 2)

Page

8 - Final Assembly (2011 page 3)

Page 9 - Completed

Aircraft

Page 10 - Later Updates and

Modifications

Page 11 - MOGAS vs

Composite Fuel Tanks

POH

for Scott Grizzly Cub N143W

Page 1 - The Cub

Project

Page 2 - Fabric

Page

3

- Firewall Forward

Page

4 - Firewall Forward (page 2)

Page

5 - O-320

Overhaul (for the Cub)

Page

6 -

Final Assembly (2010)

Page

7 - Final Assembly (2011 page 2)

Page

8 - Final Assembly (2011 page 3)

Page 9 -

Completed

Aircraft

Page 10

- Later Updates and

Modifications

Page

11 - MOGAS vs

Composite Fuel Tanks

POH

for Scott Grizzly Cub N143W