MOGAS vs Composite Fuel Tanks

Page 1 - The Cub

Project

Page 2 - Fabric

Page

3

- Firewall Forward

Page

4 - Firewall Forward (page 2)

Page

5 - O-320

Overhaul (for the Cub)

Page 6 -

Final Assembly (2010)

Page

7 - Final Assembly (2011 page 2)

Page

8 - Final Assembly (2011 page 3)

Page 9 - Completed

Aircraft

Page 10 - Later Updates and

Modifications

Page 11 - MOGAS vs

Composite Fuel Tanks

POH

for Scott Grizzly Cub N143W

Ever since this plane was new, I have typically run it on a mixture of

80% Alcohol Free MOGAS and 20% 100LL Avgas. But in December of

2017, I retired and moved from Los Alamos, NM to Cherokee Village, AR.

In New Mexico, I always bought my MOGAS from Honstein Oil as they

were the only jobber that carried Alcohol Free MOGAS.

Fortunately, my new home is in an area with lots of lakes and

boats, so every gas station carries Alcohol Free Premium fuel. As

always, I tested and confirmed there was no alcohol present.

However, in June, I took a month away from the planes and the

hangar while I had a knee overhauled. When I returned to that

hangar in July, I found the Cub leaking fuel, the O-rings in the primer

had failed,

the hoses on the fueling rig had failed and were leaking, and the flow

meter on the fueling rig on the truck had also failed. Man, that

was a lot of failures at once, and the common thread was the fuel.

I worked on the Cub to seal some leaky threads, then topped it

off with 100LL only to come back and find it leaking from both tanks

enough that it was running down the sides of the plane and dripping off

the belly and tail. It was clear that the tanks in the Cub had

been breeched and would require rebuilding or replacement.

Additionally, while this damage was not from Alcohol contamination,

there was clearly something in the fuel that was causing damage.

While I may not know what to test for, I could devise a test to

see if the fuel would cause problems. One of the things I noted

was that the fuel appeared to attack the Rectorseal (TM) Pipe Dope I

used on all the pipe fittings. So, I made a stop at some of the

local gas stations and pumped 2 gallons of premium fuel into my old

truck to clear the hoses at the pump, then 1/2 gallon into a clean gas

can. Fuel samples were taken from the gas cans and placed into

baby food jars. Then I placed a new O-ring into the jars. I

laid up a single laminate of epoxy resin and 5.85oz glass and cut into

test strips to go into the jars. Then I took a 1/8" pipe fitting,

worked some pipe dope into the threads and allowed to cure overnight

before placing the fittings into the jars.

Fuel testing. I have two controls here. Jar #1 is 100LL,

and Jar #6 is the fuel that damaged the fueling rig and the composite

tanks in the Cub. The other jars are from local fuel stations.

The pipe dope test was a very quick test and apparently accurate.

The fittings with pipe dope on them had the dope dissolve on

contact in jars 3, 4, and 6. The dope did not dissolve in jars 1

& 2. After 2 months and repeated swirling of the jars, the

pipe dope has still not dissolved in either jar. After 2 months,

the fiberglass test strips in jars 3, 4, & 5 are showing

significant degradation, while the test strips in jars 1 & 2 are

not. It appears that the clear fuel in Jar #2 is just as safe

with composite tanks as the 100LL. Unfortunately, the fuel I had

been using in my planes was from Jar #6.

4 months later - The fiberglass parts in jars, 3, 4, & 6 appear to

be significantly degraded while the parts in jars 1 & 2 appear to

be unchanged.

Terminology for this blog:

Micro - microballoons,

microspheres, glass beads - microscopic hollow glass spheres,

mixed with resin to form a smooth, super light weight non-structural

filler.

Flox - Flocked cotton - finely

ground cotton mixed with resin to make a putty like structural filler.

Milled Fibers - Finely ground

glass fibers mixed with resin to make a stronger, but heavier, putty

like structural filler.

AeroPoxy - A brand name Epoxy

resin used with either fillers or to laminate glass cloth.

West Epoxy - A slightly faster

setting (24 hrs) brand name Epoxy resin used with either fillers or to

laminate glass cloth.

Vinylester Resin - A different

type of non-epoxy resin using MEKP as a catalyst with different finish

properties. In this case, the most important one is that it will

not break down when exposed to alcohol and other chemicals that may be

found in fuels.

Divinylcel - in this case, a

1/8" core material used with laminating resins.

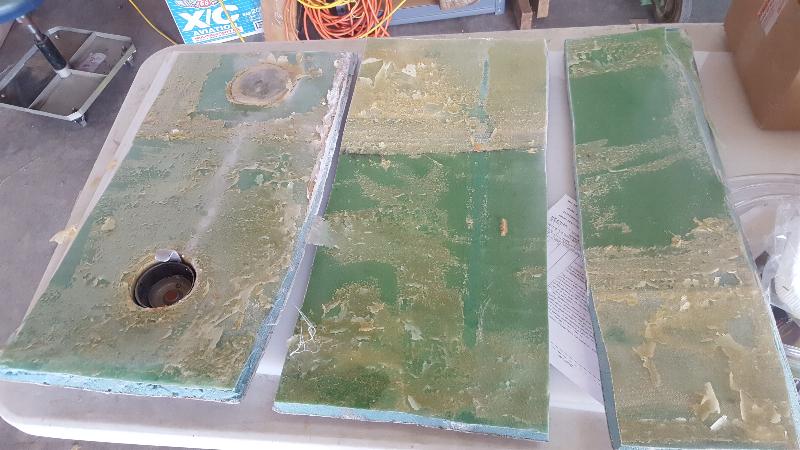

July 2018 - I've cut the fabric away from the top of the fuel tanks,

but I need to give my knee more time to heal (partial knee replacement

in June), and it's just too hot for

this kind of work in Arkansas in July.

September 26, 2018 - It's fall weather and my knee is healed. So,

I cut the top from the fuel tanks. Wow! All this debris is

apparently a coating of epoxy resin painted onto the inside of the tank

to seal it. It simply broke down and peeled off inside the fuel

tank. It's somewhat horrifying to know this is what the insides

of my tanks looked like while I was flying!

The inside was also peeling from the bottom of the top of the tank.

The tops fell apart when I cut them off, so will need to

fabricate new tops.

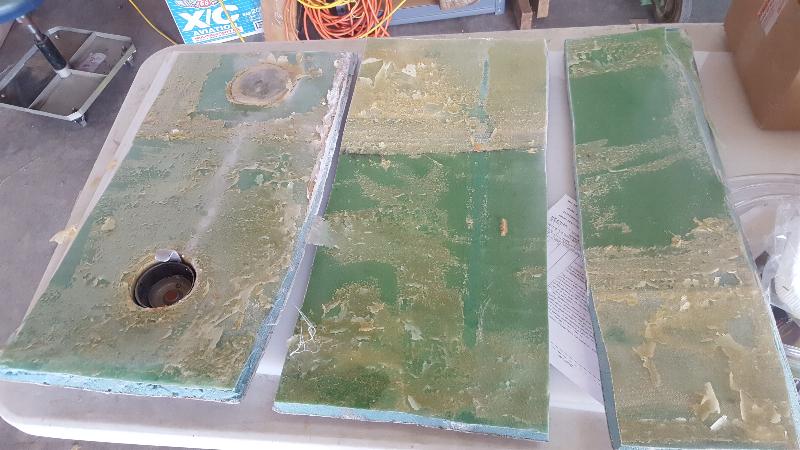

This is the left tank after cutting away the top in three sections

leaving the ribs in place.

This is the right tank after cutting off the top. It's not

quite as bad, but it's still pretty ugly.

This is the right tank after cleaning it up. It still needs a bit

more clean up, and will require laminating some glass on the inside to

build it up some before sealing it with slosh compound, but it will be

repairable.

Here is the left tank after the initial clean up. These tanks

were built with 3/8" blue foam as a core material. It delaminated

while cutting it away, so I am likely going to need to fabricate new

tops for the tanks. I'm still mulling over how I plan to

accomplish that task.

Sept 28, 2018 - I've had a couple of days to consider the repairs on

these tanks. I really don't trust the various penetrations into

the tanks to be sound. As you can see in the photo above, most of

the penetrations are at the butt end of the tank for obvious reasons,

and I simply do not have access to them with the wings on the plane.

So, the wings are going to have to come off to gain access to the

butt end of the tanks, and to give me better overall access to build

these tanks new. At this point in time, I am still undecided

about whether to build with epoxy resin and slosh to seal, or build a

new tank within the existing tank using VinylEster resin.

Fact is, VinylEster is the only resin that will not deteriorate

due to fuel and fuel additives. On the other hand, I have epoxy

tanks in my KR with slosh compound that have served me well for 21

years now. Additionally, I have a lot of epoxy resin and the

slosh compound on hand, and would need to buy the VinylEster.

That's not a huge expense, but the final factor is that I really

don't like working with VinylEster, which is probably the biggest

factor. So, for now, it's undecided. First I need to get

these tanks off and do some more clean up before I make the call.

I also have to take a closer look at cutting out the ribs and

fitting a metal tank into this space. That may yet also be a

possibility. But the one conclusion I can make is that this plane

is not going to fly again in the near future. Glad I gave the

engine a full treatment of Cam Guard at the last oil change.

October 1, 2018 - Wing tips are off, control cables disconnected,

electrical disconnected, and fuel lines are removed. I've built a

set of wing jacks to hold up the wings while I remove them. Only

thing left to do is pull the bolts from the lift struts and wing attach

fittings, and the wings will be off. Then I can get serious about

rebuilding the fuel tanks. The decision on the resins is made.

I have to rebuild these with vinylester if I want to ensure that

this type of problem doesn't happen again.

October 3, 2018 - OK. Here she sits looking like a plucked

chicken.  The wings are on

the bench to have the tanks rebuilt.

The wings are on

the bench to have the tanks rebuilt.

The epoxy resin in these tanks is badly degraded. You can see a

lot of bare cloth as well as a lot of peeling resin and cloth.

All the various penetrations into the tank (fuel pickup, fuel

site gauge ports, fuel drain) are all compromised and leaking, so they

all have to come out.

The baffles are all out. There are a lot of really rough areas in

the tanks that need to be sanded, and some holes that need to be filled

with micro before laminating the inside of the tank with vinylester and

cloth. You can see several of the penetrations have now been

removed from the tanks. The tank drain won't be removed until I

get the new welding flanges in so I'll know how big or small of an area

to cut to install the new flange.

October 4, 2018 - Today I ground away a ton of flox, foam and other

materials from the the rib former spanning the top of the tanks.

I also ground down all the stubs and flox points from the various

baffle plates and supports that had been in the tanks. The new

tops will fit under the steel rib formers and get floxed to the

formers. The red markings in the tank are areas that will need

some repair with micro-balloons before I start laminating with

vinylester. In this photo, you can clearly see the penetrations

where I knocked out the fuel pickup and the tank gauge ports.

Those will eventually get aluminum flanges floxed into place for

the fuel and vent ports. Tomorrow... More sanding. Woohoo!!!

Oct 5, 2018 - I've completed the rough sanding of most of the tanks.

I filled some of the really rough stuff with Micro today.

Will sand more tomorrow. The idea here is to get the

surface smooth enough that I can laminate over it with vinylester resin

and tooling cloth to start building a tank within the confines of the

old tank.

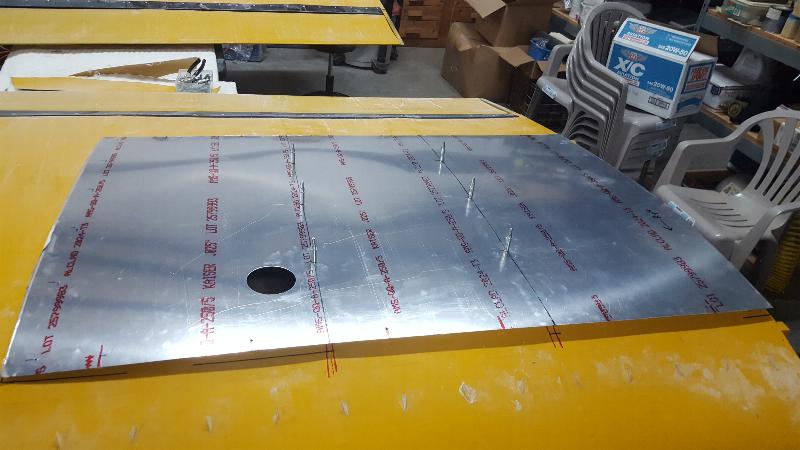

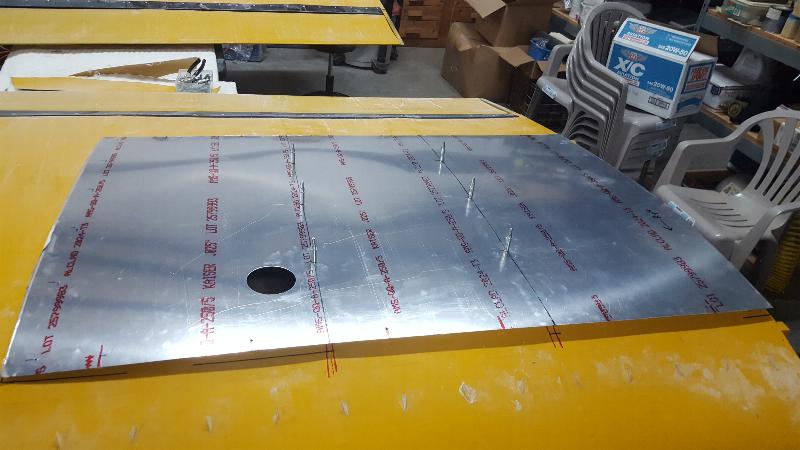

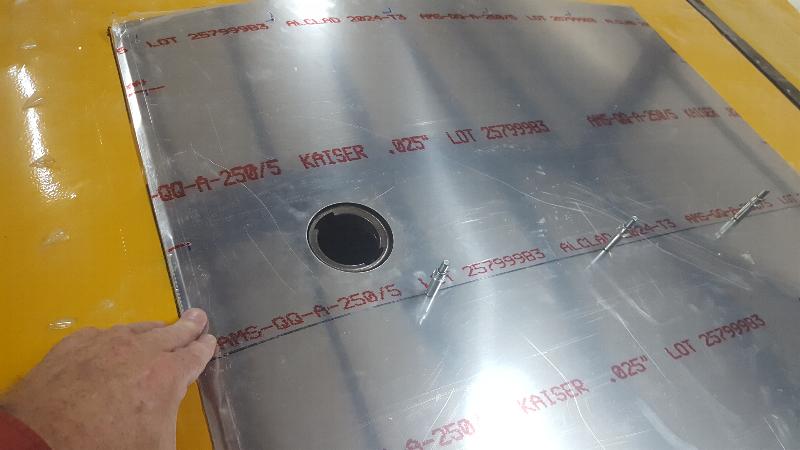

Oct 8, 2018 - Started fitting up the new tank covers. With the

Aluminum tank covers, I can easily gain access to the new tanks to

inspect or repair if there is a problem in the future. Also

cleaned up the filler necks and welded a new flange onto one to prepare

for installation back into the tanks.

Oct 9, 2018 - Today's project was to drill and fit the aluminum welding

flanges for the various tank penetrations. These will get floxed

into place, then glassed over. Left to right these are Fuel Sump,

Fuel Pick Up, Vent return from header tank, lower port for the Fuel

Sight Gauge, and the

far right side at the top is the upper port for the sight gauge.

These flanges had to be drilled with numerous holes so the

flox will have something to bite into, then cut down to fit along the

upper and lower edges. I also drilled out the sump drains.

I left the bottom plate from the drains in place as I had

overdrilled the fitting to where it won't be in the way.

Oct 10, 2018 - Cheap Vacuum bagging (a.k.a. vacuum garbage bagging).

I am laying up the baffle plates to go into the fuel tanks.

I'll cut them out of flat sheet, so need a sheet of material

strong enough for the job, but yet light. This material is made

up of one lay up of 5.85oz glass on either side of a piece of 1/8"

divinycel foam core. To make the piece easy to attach, it will

have a peel ply finish on both sides. The lay up

from bottom to top is peel ply (dacron fabric), 5.85 oz tooling glass,

1/8" divinycell foam (perforated from both sides with a porcupine),

tooling glass, peel ply,and absorbant breather cloth. It is

covered with a plastic painting drop cloth from WalMart, and sealed

using latex caulk. This is laid up on an old piece of formica

countertop I got for the asking, then waxed with floor wax. This

makes for a really inexpensive vacuum bag, and works equally as well

for flat lay ups. This is also the beginning of building this

back up using vinylester resin. It's been 22 years since I last

used VinyEster, so I needed to refresh myself a bit on the amount of

catalyst to use and the flow qualities of vinylester. I still

don't like the stuff, but it's what I need if I want chemical proof

composite tanks.

Oct 11, 2018 - First lay ups of vinylester in the tanks. I

laminated the front and back walls with a single lay up of vinylester

and tooling cloth. The "plyfoam" part I laid up yesterday looks

good, so I laid up a second one today. That should be enough

"plyfoam" to fabricate two baffle plates for each tank.

Oct 13, 2018 - Floxed in the various tank penetrations; from left to

right - Fuel Sump, Fuel Pickup, Header tank return line, lower and

upper ports for fuel sight gauge. This is just the first pass to

get the welding flanges attached in the right places. They will

get more coverage and glassed over before I'm done.

Also laid up more pieces for the tank tops, but really nothing to show

picture wise. They all look the same as the vacuum "garbage" bag

lay ups on Oct 10.

Oct 15, 2018 - Punched a hole for the filler neck in both tank tops

today. Also drilled the finish sizes for all the attach screw

holes in the panels. I need to use a hole duplicator to locate

and drill the holes in the butt rib so they match up with the overlying

fairing. I had a hole duplicator before I moved, but don't seem

to have one anymore. Will have to order a new one. Once the

butt rib holes have been match drilled, Some corner clean up

accomplished and a little leading and trailing edge work completed with

my press brake, the tank covers will be ready to prep and paint.

Also still fabricating pieces for the tank tops. One per

day. Time to take the next week off for some family travel before

I continue with the work.

Oct 22, 2018 - Used my mini-Press Brake to bend a front and trailing

edge onto the aluminum tank covers. These covers are now ready to

be acid etched, primed and painted. Also used a hole locater to

locate and match drill the holes in the tank cover to the holes in the

butt ribs. Also laid up another section of the tank top.

Two more pieces to go before I can start cutting and installing

the tops.

October 23, 2018 - I glassed in the remainder of the bottom of the tank

as well as the butt end of the tank with vinylester and tooling cloth.

This completes the glassing of the tanks themselves. They

will still get cleaned and prepped, then coated with KBS sealer before

I attach the tops. The green color of the vinylester resin

doesn't seem to show very well in the photos, but the insides of the

tanks are completely lined with a minimum of 1 layup of tooling glass

and vinylester resin, with 2 - 3 reinforcements layups in the corners.

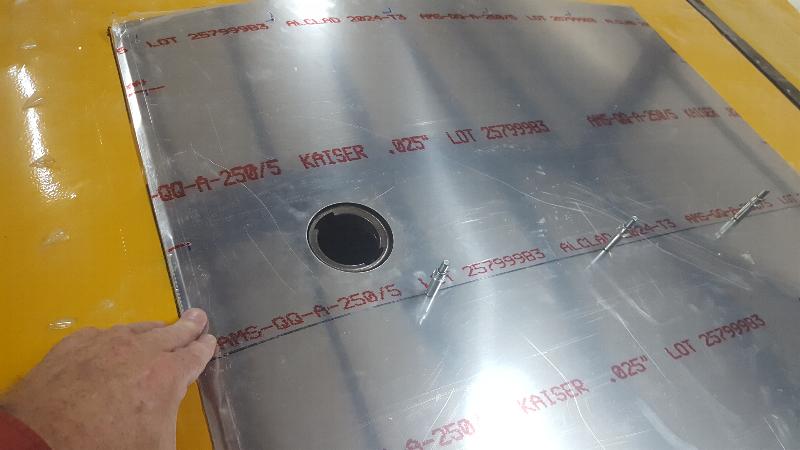

October 24, 2018 - This is a very big step that I have been worrying

about for a month or two now. I have fitted up the first section

of top and have it ready to go onto the tank once the tanks have been

coated with a slosh sealant. It's hard to tell from the photo,

but it fits very nicely. The small X at the top of the tank cover

is the centering hole for the filler neck, which is being relocated to

the outer cell of the tank.

October 25, 2018 - Today I cut out the tank baffles and fitted them to

the tanks. The baffles are made up of 1/8" Divinycell with a

single lay up of 5.85 oz tooling glass on each side with vinylester

resin.

Note that with the exception of the main fuel pickup, all the

welding

flanges are now glassed in. The main fuel pickup is also floxed

into place and glassed over. It just doesn't show in the picture.

October 26, 2018 - I used my 3-1/8" punch to punch the hole for the

fuel filler neck into the outer bay. The top for the tank is

fitted, but

not attached.

I also cut out and fitted all the rest of the top pieces as well as the

shims to shim the fuel filler neck up into place to fit the tank cover.

Filler neck shimmed into place on the tank top with the tank

cover in place.

The tanks were cleaned and prepped, so are ready to apply the KBS slosh

sealer tomorrow. The white tape is masking to leave a strip with

no sealer where I'll bond the ribs underneath the tops when I attach

the tops. The angular wedges along the white masking are stops to

push the ribs up against when I install them.

October 27, 2018 - Fuel tanks have two coats of KBS slosh

compound/sealer.

October 28, 2018 - Slow day. Installed the finger strainers in

the fuel pickups.

Tomorrow I'll start attaching the top pieces.

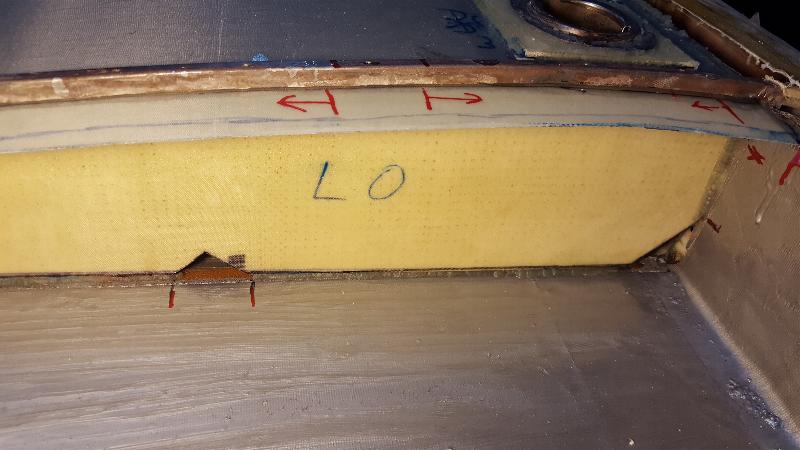

October 29, 2018 - The inner and outer bays have the tops on, and the

filler neck was installed in the outer bay. Note the gray color

of the tops as they are now coated on the inside with KBS tank sealer,

except where I will be bonding them to the edges and to the center top

piece.

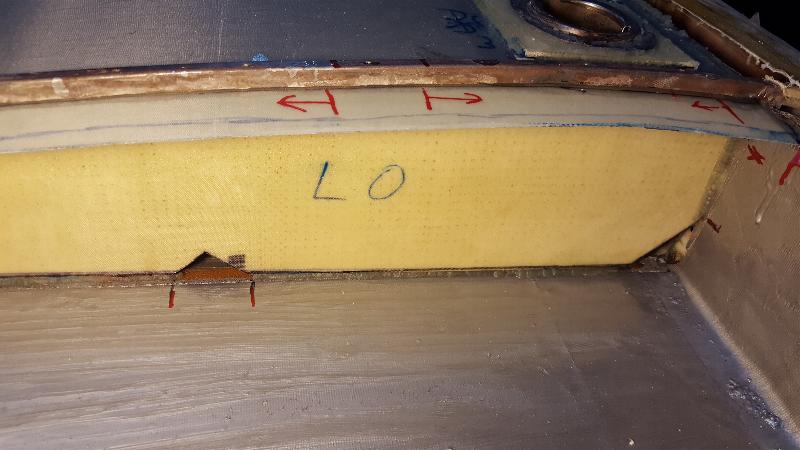

October 30, 2018 - I bonded the tank baffles/inner ribs into the tanks,

then closed out the tanks. (LO = Left Outer Rib)

The tops are on. The white strips are 1/8" perforated divinycell

with micro around the edges and a single lay up of glass over top.

These are there to stiffen the tops of the tanks and make them

rigid. At this

point in time, the tanks are done. Yippee!!  I still need to install the fasteners

in the wing to hold the tank covers on, and the tank covers need to be

primed and painted. And, of course, I need to put the wings back

onto the plane, rig the controls, and do some other reassembly and

repair work. I should be ready to put the wings back on early

next week.

I still need to install the fasteners

in the wing to hold the tank covers on, and the tank covers need to be

primed and painted. And, of course, I need to put the wings back

onto the plane, rig the controls, and do some other reassembly and

repair work. I should be ready to put the wings back on early

next week.

November 1, 2018 - I fabbed up a 4th pair of wing jacks. Copied

this design from a friend in Los Alamos (thanks Skip!). This

airport seems to be pretty sparse of pilots and pretty sparse on help

when I need extra hands. So, I have two sets of wing jacks.

I'll line them up with two jacks on either side of the plane,

then set the wings on them. When I run the threaded rod up, it

lifts the wings into place so I can put them on by myself. That

way I'm not trying to get the bolts into the spar fittings or hang the

lift struts while I've got helpers fidgeting about telling me their

arms are tired and need to set the wing down. The wing jacks make

life easier for everyone, and are a serious consideration when you live

in a community where everyone is over 60.

November 2, 2018 - Norm and Jim were kind enough to help me get the

wings onto the aforementioned wing jacks. Kind of resembles a

mutant Cygnet with the wings like that. It was a simple

matter to run the jacks up and slip the spar attach bolts in.

Spar attach bolts in. Lift struts laying on the tables. I

shot a bunch of boiled Linseed Oil into the lift struts as an

anti-corrosive/sealer before I put

them on.

Lift struts on. Only a few hundred more details to address before

it's ready to fly again.

Nov 14, 2018 - Leak test failed, so the tanks are not done. I had

some weeps at the

top seam at the back of the right tank. After some

contemplation, I decided that I'm not entirely happy with the top

seams. The

weepy area of the seam was cut down, then

filled with a mixture of vinylester resin and milled glass fibers to

seal the seam. They look like a weak spot, and the floxed areas I

was

certain would seal, had some leaks. So, I used a mix of resin and

micro as a core, then laid up glass over top about 2 inches over

lapping the seams and wrapping down the side of the tanks. This

photo is after I beefed up the top tank seams.

Nov 17, 2018 - We had a warm, sunny day, so after painting a second

coat of sealer on the outside of the tanks to address any potential

pinhole leaks, I rolled it outside to sit in the sun to promote the

curing

of the resins. Everything is ready

for leak testing on Monday. If it is leak free, I still need to

get the tank covers painted, and install the rest of the wing root

fairings and it will be ready to fly. Oh yes, it really needs a

bath to get all the fiberglass dust off. This is the first time

the Cub has been out of the hangar since July.

Click on the small pictures to see a larger version.

Start.

Delaminated mess.

Clean up and

rebuild. Coated with KBS Slosh.

Tops on the tanks. Completed tops.

It's probably worth noting that I relocated the filler neck from the

inboard front corner of the tanks to the outboard front corner of the

tanks during

the rebuild.

November 19, 2018 - Leak check passed! The tanks are good to go

now. I dropped the tank covers off at the paint shop. They

should get to them the last week of the month, so the Cub should be

ready to fly around Dec 1. Today I was finally able to pull it

out of the hangar to fire it up and warm up the engine. I hate

letting it sit for so long. It was last started and flown in

July. so the engine hasn't been run in 4 months. Sure glad I have

Cam Guard in the oil to protect the cam followers from corrosion.

Decmber 6, 2018 - At long last I got the tank covers back from the

paint shop. I have to say, they did a really nice job with a good

quality self etching primer on both top and bottom, and did a nice job

shooting the Acrylic Urethane finish paint I supplied to them.

It is all together again. This plane has been

grounded since I discovered the extent of the tank damage in July.

I can hardly wait to get a nice day to go play!

May 2, 2019 - I've had a really annoying, but minor weep in the right

fuel tank ever since I put this back together. It was never

enough to even drip. Just enough to smell fuel, and stained the

bottom of the tank with blue dye. I have intentionally run

nothing but 100LL in it in hopes the dye in it would reveal the weep

when I got to doing the annual. So, now it's time for the annual.

I found a bunch of dye all over the wing root bulkhead of the

tank, so washed it all out with solvent yesterday. After sitting

overnight, today there is a trace of dye showing the source of the weep.

You can see the blue dye marking weep towards the top of this seam,

then the dye runs along the seam as the fuel creeps along the seam..

I drained the tank after this photo was taken, then washed it

down with solvent again, then a soapy prep solution, rinsed with water,

then an acid etch and another thorough water rinse. I'll let it

dry tonight, then will effect repairs tomorrow.

May 3, 2019 - I sanded, then painted with vinylester resin, then a

brushed on coat of vinylester with milled fibers, then 2 coats of KBS

sealer to ensure no more weeps.

May 2020 - I still had some weeps in the same place as above on the

right tank. I cleaned and sealed some more. That

seems to have cured it.

Oct 2020 - I've been getting stronger and stronger fuel smells for the

last few weeks. The left tank started dripping fuel, so I

defueled the

plane and parked it in the back corner of the hangar until I had time

to deal with it. After removing the tank cover, I could see where

fuel

had been on the fabric, but didn't find any stains on the tank itself

indicating where it had been leaking. Above the fuel stains was

the

rib, which had been really difficult to work around while attaching the

top to the tank during the rebuild. So I decided to do a repair

there

even though there was no solid evidence as to exactly where the leak

might be. If that didn't fix it, I was going to buy a set of

Dakota Cub aluminum tanks and would be pulling the wings off to install

those tanks. The photo above is prior to doing the repair. I

didn't take a photo of the repair as I really didn't expect it to work

and was expecting to be pulling the wings off the plane. However,

after a couple of days for the repair to cure, I fueled the plane and

found no fuel smell and no leaks. It has now been a week and so

far, all seems to be well. No fuel smell and no leaks. I'm

not convinced that I won't still be replacing these tanks at some point

in the future, but for today, they seem to be good.

Page 1 - The Cub

Project

Page 2 - Fabric

Page

3

- Firewall Forward

Page

4 - Firewall Forward (page 2)

Page

5 - O-320

Overhaul (for the Cub)

Page 6 -

Final Assembly (2010)

Page

7 - Final Assembly (2011 page 2)

Page

8 - Final Assembly (2011 page 3)

Page 9 - Completed

Aircraft

Page 10 - Later Updates and

Modifications

Page 11 - MOGAS vs

Composite Fuel Tanks

POH

for Scott Grizzly Cub N143W)

The wings are on

the bench to have the tanks rebuilt.

The wings are on

the bench to have the tanks rebuilt.

I still need to install the fasteners

in the wing to hold the tank covers on, and the tank covers need to be

primed and painted. And, of course, I need to put the wings back

onto the plane, rig the controls, and do some other reassembly and

repair work. I should be ready to put the wings back on early

next week.

I still need to install the fasteners

in the wing to hold the tank covers on, and the tank covers need to be

primed and painted. And, of course, I need to put the wings back

onto the plane, rig the controls, and do some other reassembly and

repair work. I should be ready to put the wings back on early

next week.