Firewall Forward

Page 1 - The Cub

Project

Page 2 - Fabric

Page

3

- Firewall Forward

Page

4 - Firewall Forward (page 2)

Page

5 - O-320

Overhaul (for the Cub)

Page 6 -

Final Assembly (2010)

Page

7 - Final Assembly (2011 page 2)

Page

8 - Final Assembly (2011 page 3)

Page 9 - Completed

Aircraft

Page 10 - Later Updates and

Modifications

Page 11 - MOGAS vs

Composite Fuel Tanks

POH

for Scott Grizzly Cub N143W

Here's the engine. This is a Lycoming O-235-L2C (118 HP

@2800 RPM). It sat for a while before I

bought it and has some internal corrosion problems. I bought

this engine as a spare to rebuild for my Tomahawk,

but never needed to use it. I'll overhaul it and

mount it

on the Cub. I may rebuild it as a high compression

O-235-L2C-M, which would make it 125 HP @ 2800 RPM. The

upgrade requires different pistons, different

spark plugs for clearancing reasons, and the addition of an oil cooler.

OK, scratch that idea. I found an O-320 that I just couldn't pass

up.

I'll create an O-320 web page to show the

major overhaul.

Oh, I wish I wish. Nope the engine is just on there so I can fit

up the cowling. The engine is still slated for

overhaul this

fall/winter. But it does look great having it on there for a

while!

August 29, 2010 Ah. It's sprouted a nose! I have cowl

pieces, but no plans for a cowl. It's been interesting

as all the parts books show the parts I have, but the high dollar cowl

latches I bought from Wag Aero won't

work with the cowl configuration as shown in the SuperCub parts book.

However, by looking at lots of

other Cub projects on line, I was able to figure out how to configure

the lower braces to get everything to

fit properly. Thanks to everyone else that posts their pictures

to the web.

Nose bowl head on.

September 7, 2010 - I've finally got all the fasteners in

and the cowl fitted together. There photos are the

final product before I disassembled it to get ready for prime and

paint. Each cowl cheek still needs a small

stiffener installed, otherwise it's complete.

September 9, 2010 - Patch installed in the mystery hole in the top of

the boot cowl. I haven't a clue why that

hole is in there, but I

can't see any reason why I'm going to need it, so I patched it.

Hmm. Twins??? Twin engine Cub??? Nope. I found

a good buy on an O-320, so decided to go for the

bigger engine. That's the O-235 I was planning to use with the

mount still on it. Next to it with all the accessories

still mounted is the O-320. Right now, I'm inclined to major the

O-320 so I can start out with a fresh engine.

Feb 7, 2011 - I bought this prop on Barnstormers. It's a 74 x 58

Sensenich. It's the right diameter and should be

about right for pitch for a 160 HP O-320 on a Cub. The

engine is progressing, although there is nothing to show

via pictures. It's all written up on the O-320 overhaul page.

Feb 15, 2011 - The new prop arrived today. It's gorgeous despite

the beating it took with UPS.

March 11, 2011 - I have finally convinced myself that the engine mount

just isn't right. I found a knowledgeable

SuperCub owner at the Cactus Fly In last weekend who advised me that

the engine mount should have 4 degrees

of down thrust. Now I have something to measure to, so I took

some measurements on the high $$ mount I bought

from Wag Aero. It has 8 degrees of down thrust built into it.

That is HUGE! I did a calculation and found that it

would need 7/10" for a shim on the lower mounts to straighten the

engine out. There is no way that is going to work

with a dynafocal mount. So, now I need to cut that expensive

mount apart and rebuild it correctly. Yes, I am

bummed, and just a little bit peeved at Wag Aero. Of course I

bought this mount a year ago, so they aren't going

to want to talk to me about it now. :o(

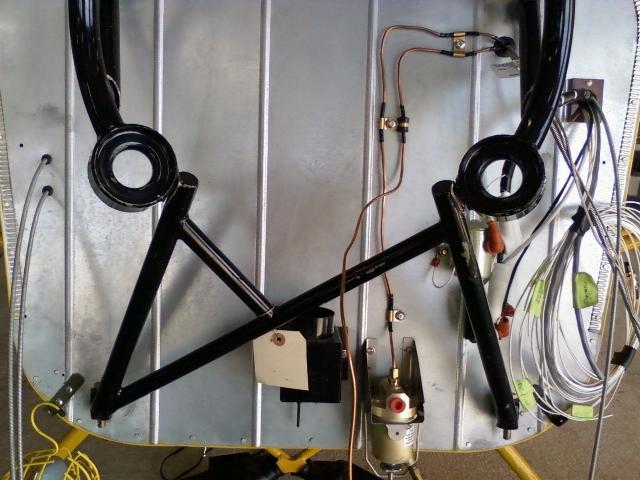

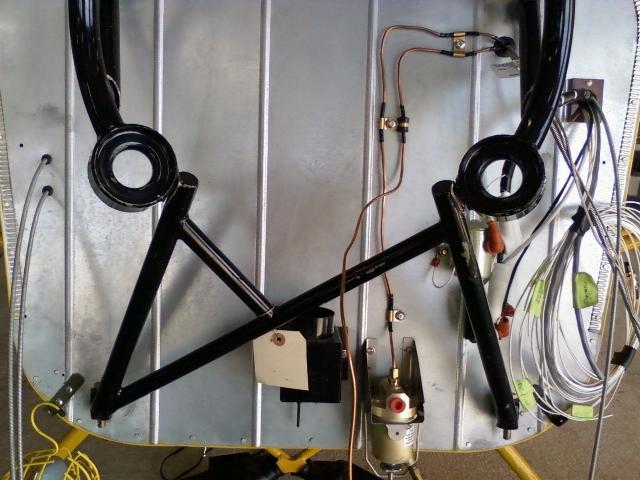

March 13, 2011 - I cut the engine mount apart so I could set the

downthrust correctly. Note that both braces

from the bottom for the fire wall are cut free from the dynafocal ring.

I don't have a picture here, but also had

to cut off the lower 3/4" cross brace and sleeved it with a piece of

7/8" tube.

I also cut off the upper brace that connects to the lower part of the

ring.

I cut most of the way through the top brace, then bent the bottom of

the dynafocal ring out to raise the engine

4 degrees.

The mount is all tack welded back together. The 7/8" upper brace is now

sleeved with two halves of a 1" tube.

The bottom brace is tack welded back onto the ring.

I also sliced through most of the lower attach point. It is tack

welded back on, but will get a wrap around sleeve.

The top brace is tack welded at the top. It will also get a wrap

around sleeve.

March 18, 2011 - Stress relieving the finish welded engine mount.

The mount was sliced and diced. I cut

it in 9 different places, then spent two evenings welding it back

together and adding doublers to some welds

that I thought might be vulnerable. I relieved it a couple of

times during the process to keep it close enough

to be able to force it over the mounting tabs. I heated and

relieved the mount at all of the welds. Once the

relieving was done, the mount easily slides into place and the bolts

drop in without pulling and forcing the mount.

March 19, 2011 - Engine mount shot with primer.

March 20, 2011 - Engine mount finished in black.

April 23, 2011 - Back to firewall forward work. The freshly

overhauled engine is hung on the plane.

I added the prop just for show. I'm ready to go fly this!!!

Page 1 - The Cub

Project

Page 2 - Fabric

Page

3

- Firewall Forward

Page

4 - Firewall Forward (page 2)

Page

5 - O-320

Overhaul (for the Cub)

Page 6 -

Final Assembly (2010)

Page

7 - Final Assembly (2011 page 2)

Page

8 - Final Assembly (2011 page 3)

Page 9 - Completed

Aircraft

Page 10 - Later Updates and

Modifications

Page 11 - MOGAS vs

Composite Fuel Tanks

POH

for Scott Grizzly Cub N143W