2024 - 2025 Elevator Trim Redesign

Engine overhaul

Electronics/Electrical

Fuel System

Trim System

Fabric Recover

Item #1 from the rebuild page: The trim is inadequate.

It's barely adequate when I have a full tank and a passenger in

the front seat. Otherwise I run out of nose down trim. If I

take the front windscreen off, the plane wants to dive at the ground

even with full nose up trim. So, the spring biasing trim is going

to go away in favor of two Ray Allen trim servos; one mounted in either

elevator. The hinges are already there as it apparently had trim

tabs on it in the past, but they were removed for unknown reasons.

I see there is an abandoned bowden cable in the aft fuselage, so

I suspect that used to be the trim control.

There are no tabs installed on the elevators, but notice the three

hinge points welded to the trailing edge of both elevators. I

plan to take advantage of those hinge points and will use them to mount new

trim tabs that will work in sync with each other.

The old trim system. The handle on the left side of the rear

cockpit is the existing the trim system in the plane. It is a

push/pull bowden cable that pulled on a spring (in the photo

below) to bias the elevator nose down. There was no nose up trim.

By myself, depending on the fuel load, the plane wanted to fly at

about 80 - 85 mph. I could pull in some nose down trim, but it

was inadequate once I had burned off half of the 20 gallon fuel tank.

Additionally, I have quarter turn fasteners to remove the front

windscreen and an aluminum cockpit cover for the front cockpit so I can

fly it with a slick front cockpit. When I tried the slick front

cockpit configuration, the plane just wanted to dive at the ground with

no ability to trim it nose up. This spring bias trim system has

now been removed from the aircraft.

12/19/2024 - The

project to redesign the elevator trim. It currently has a

lever in the rear cockpit that pulls on a spring to bias the elevator

nose down. There is no nose up trim as the plane wants to fly

almost down to approach speed hands off. If I remove the front wind screen,

the plane wants to dive at the ground. With no nose up trim available, I

can't fly it slick with the front windscreen off and the front cockpit cover

on. I'm adding an

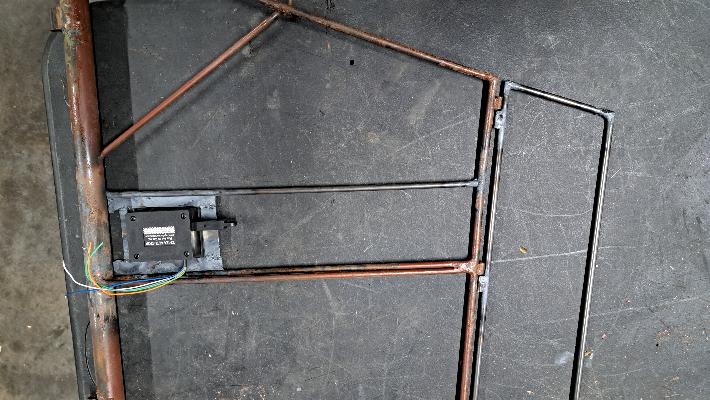

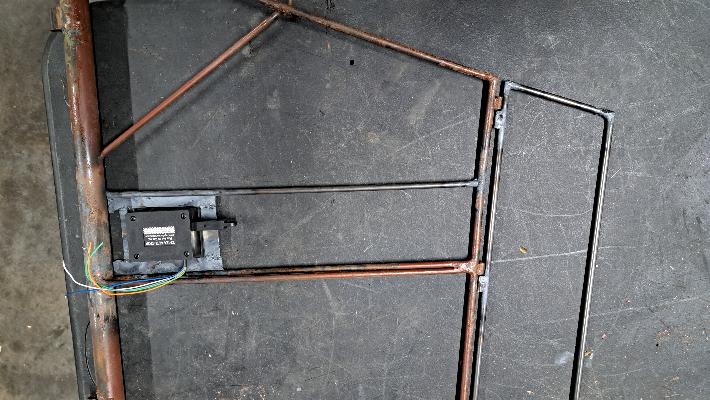

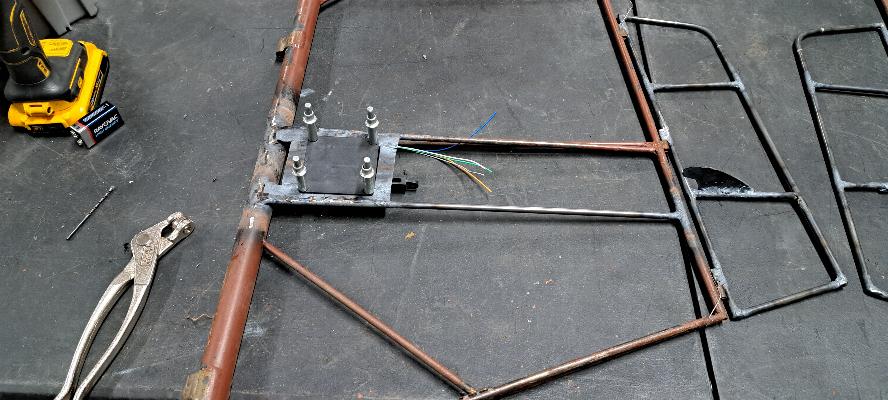

adjustable trim tab to each elevator. Above, I have the elevators

removed, and below I have the outer edges of the trim tabs welded

together. I'll add the bellcrank and internal structure after I

cut the elevators open and figure out where and how to mount the trim

servos.

12/20/2024 - Today's the day to get after the trim modifications.

I stripped the fabric from the left elevator, so orientation

wise, we are looking at the top of the left elevator in the photo above, and the bottom below. The Ray Allen

trim servo is in the bottom left of the corner of the top photo and gets mounted into the elevator from the bottom. .

First thing was to weld in a brace and frame to mount the trim servo.

Just the two sides would be enough to hold the servo. The

complete picture frame to go around the servo is to give me a place to

attach the fabric around the hole. The outer face of the servo

will be exposed on the bottom side of the elevator.

Turned over right side up so we are looking at the top of the elevator.

This part of the servo will be under the fabric.

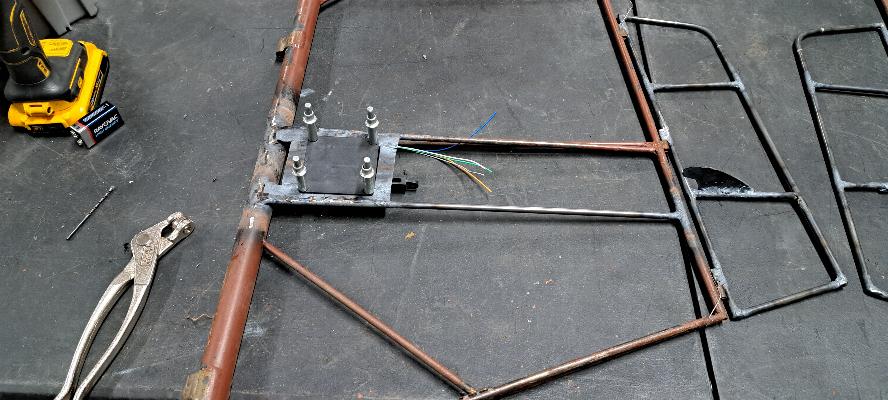

Working from the bottom side of the elevator again. Inner

framework is welded into the trim tab and the bellcrank arm has been

fabricated and welded to the tab. The bellcrank is two pieces of

.032 4130 steel welded together to make it .064" thick. I cut

them out with my hand held band saw, then welded them together before

welding the bellcrank to the trim tab.

Almost completed assembly. I still need to add nut plates to the

mounting frame for the servo and customize a piece of 10-32 threaded

rod to go to the trim tab for control. I also plan to duplicate

this same structure and trim tab on the other elevator and will use

dual trim tabs.

12/21/2024 - Rinse and repeat from yesterday. Fabricated the same

servo mount and trim tab structure for the right elevator.

12/23/2024 - I have the Ray Allen trim servo attached to the mounting

frame with a cleco clamp. Rather than drilling and installing nut

plates, since this is mounted into 4130 steel plate, I decided to

thread the plate with a 6-32 tap and that seems to be a firm mount.

I fabricated the linkage from the servo to the trim tab with 10-32

Stainless threaded rod. Ray Allen sends #8 threaded rod in the

kit, but it was too short to meet my needs and with the longer reach, I

wanted a bit stiffer linkage. I drilled the clevises from #8 to

#10 sized and tapped them with a 10-32 tap. I did the same with

the trim on my SuperCub when I built it and it has served me well for

the last 10 years. This is full nose up trim and the photo below

is full nose down trim. I only took photos of one elevator as the

other looks just like it; only a mirror image. Those that look

closely will notice the trim tab is not straight. These things

warp and bend like mad while torch welding. A bit of gentle

persuasion with a plenishing hammer on the anvil squared it up.

Time to install the new stick handles to include the trim control.

As always, I get ahead of myself and forget to take pictures, so

at this point I have already trimmed the plastic bicycle grip handle

off the stick. I needed to sort out the wiring to the switch in

the stick as this plane has a switch activated intercom as well as the

PTT in the same switch. Just toggle it the other way. It

had some strange wiring in the way the switch was wired, but I figured

it out and will be ready to splice it to the wiring from the new stick

handle.

I cut the top of the stick off with a pipe cutter. That makes for a nice even cut.

The bushing on the bottom of the stick goes into the pipe, then you

match drill a hole in the front of the existing stick to bolt it in.

Once that is fitted to the stick, I also drilled a divot into the

front of the stick shaft for the set screw in the front to seat into,

firmly locking the stick into place.

Same treatment for the front cockpit as well. I thought the front

stick was wired for intercom only even though it had been labeled for

both Intercom and PTT. Nope. Most of the wires connected to

the switch were broken. I guess I'll wire it correctly to give

the front seat access to the radio as well. The red button on the

left with be the PTT for the radio and the gray button on the right

will be the intercom. The round button in the center will trim

nose down when pushed forward and nose up when pulled back. There

are additional buttons on the stick, but they will be unused.

I really should do something with the paint on this front instrument panel. That is UGLY!

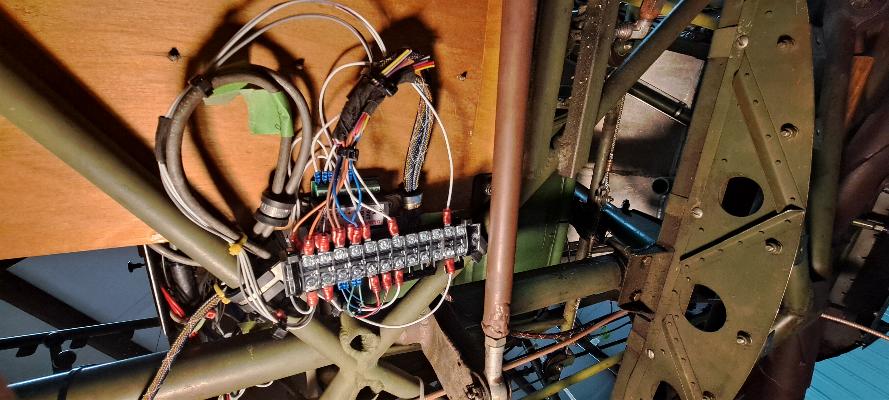

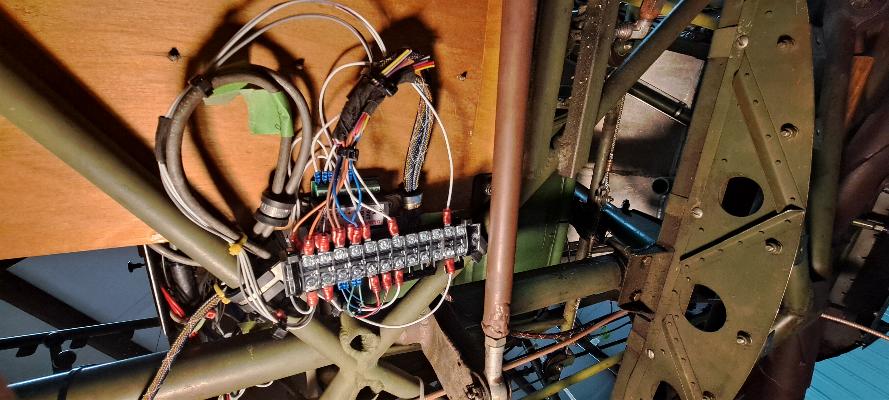

12/24/2024 -Christmas Eve... Today's goal was to wire in the

switches for the new stick grips. The switches on the stick

control elevator trim, radio transmit, and intercom transmit and all

are active from either seat. I decided to add a terminal block

under the right rear floorboard along with the relay deck for the

trim servos that came with the stick grips to enable the trim servos to

be controlled from either seat. You can see the relay deck just

under the wiring connected to the terminal block. I still need to

pull a ground wire, +12V wire, and the two servo leads to complete this

part of the installation. I also need to wire in the trim

indicators in the instrument panel. I failed to take a photo, but

today I also fabricated a new panel mount for the trim indicators and

painted it black. It will show up in the next round of wiring

when I install the indicators. I'm waiting for some mini-Molex

connectors to arrive to complete the connections, although I can pull

the wiring to the tail now. The connectors should arrive on

Friday.

12/26/2024 -

The terminal block under the floorboard is completed.

I needed to gain access to the aft fuselage to route the

wiring for the trim servos. I am waiting for some components to

arrive to complete the wiring, so I'll do some more disassembly and

strip some fabric.

Tail braces are hanging loose and labeled.

Horizontal stabs removed.

12/29/2024 - The connectors I've been waiting on arrived in

yesterdays mail. The new trim system is now completed and

functional. Note the trim indicators lit up on the right side of

the panel. Trim is actuated by pushing fore and aft on the button

at the top center of the stick. Both trim tabs are actuated with

the same button and run in sync with each other. If, for some

reason, they get out of sync, I can simply run the trim to the end of

the travel until both servos register at full travel, then when they go

the other way, they will be in sync again. The control works from

either

seat, but the indicators are only in the rear seat.