Marquart Charger O-360-A1A Engine Overhaul

Engine overhaul

Electronics/Electrical

Fuel System

Trim System

Fabric Recover

Items #4 & #5 from the rebuild page:

Top overhaul of the engine and replace the tired magnetos. This is a strong running

engine, but also uses a lot of oil despite the fact that it really

doesn't leak. That says it has either oil ring or valve guide

issues. I bought new Superior cylinders and some 10:1 compression

pistons for it, so will add a bit of HP in the process.

This was supposed to be a simple top overhaul of the engine on my

biplane, but once I got into it, things kind of snowballed. So, I

created a separate page for the engine. This engine is a prime

example of why, when I shop for a plane, I always look for one in need

of an overhaul. Invariably, the first time I open up the engine,

I find all kinds of things that give me heartburn, to I inevitably end

up doing a complete major. So, with this engine completed, I will

have majored the engines on all three of my current planes.

11/8/2024 - I removed the cowling, baffling, and ultimately the top end

on the engine with a plan to do just a top overhaul on the engine.

O-360-A1A. Easy Peasy. While this engine wasn't an oil leaker, it sure is filthy looking.

I thought I had seen most everything in these engines. But, I have

never torn down a Lycoming that used drilled rod bolts and castellated

nuts. The small Continentals do, but not Lycomings. I guess they did

use them back in the 60s, and it's likely the previous overhaul re-used

the rod bolts and nuts. Perhaps that was acceptable in 1969.

It's not anymore. Rather than cotter pins,

this had roll pins driven into the holes in the rod bolts, then the

ends of the roll pins hammered

down to spread them out. Now that was a royal pain to get out as

each roll pin had to be drilled with my angle drill to remove the ends

of the roll pins. I broke 3 of the short angle

drill screw-in bits, so that was about $15 worth of bits that I trashed

getting those roll pins out.

11/9/2024 - My plan was to send the connecting rods to my buddy in

Santa Fe to have them balanced, then put the engine back together again

as I have another engine project arriving later this month. Well... That plan went down the toilet this morning.

What is that I see? Corrosion on the cam follower? That

corrosion will lead to cam spauling, so my top overhaul just turned

into a major overhaul. The cam does not appear to be damaged yet, but I won't know that for

sure until I get it out to inspect. Most of the cam followers are showing varying degrees

of corrosion, so I expect they will all need to be replaced.

Some folks expressed that they didn't see the failing cam follower

(tappet, lifter body). Here's a photo of two of the cam

followers from the engine. All the pitting on the face of the one

on the left will act like a machine tool to grind away the lobes from

the cam shaft. The cam follower on the right shows some mild

pitting and could probably be reground. I chose to replace them

all rather than using a mix of new and reground.

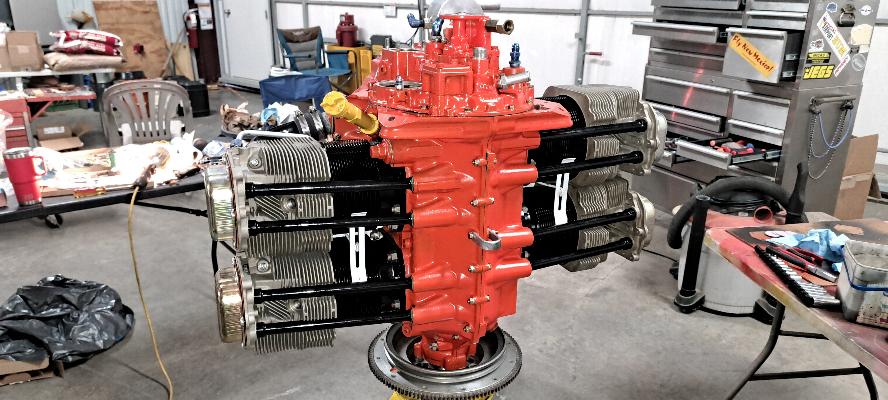

Here we are with the engine off the airframe. I'll split

the case this week and start cleaning parts. I should get

everything cleaned and put away, or prepared to go to the machine shop just in time for the other engine

(angle valve 200 hp IO-360) to arrive. The IO-360 has a cracked

case, but is also due for Major Overhaul as well, so it's going to be a busy shop for a while.

11/11/2024 - Veteran's Day. I did my time for the country. Did you?

A rounded intake lobe above, and pitted cam lobe below. Other

lobes had more of the same. This cam goes in the trash.

I need a camshaft and 8 cam followers. The rest is cleaning up good. The

mains on the crankshaft and the rod pins are nice and smooth and

measure to new specs. I'll still polish them before engine assembly.

11/12/2024 - I can't tear the engine down any further than this.

I have a bit of a delima with this crankshaft. It has some

corrosion pitting in an area that doesn't touch the bearing surfaces

(actually right between the two supporting surfaces of the front main..

But, the bearing surfaces of the crank look really good and mic

out to new specs. Never-the-less, the pitting is there. If

I send this crank in to a machine shop, the will grind it down within a

few thousandths of it's life or condemn it all together as a CYA move. I could spend $8500 for a new

crank, but I am also fully confident that this crank will be fine as

it is. I'm going to defer the decision until I get a chance to

polish the crank. Then we'll see how things look. And, of

course, this is an Experimental engine built for an Experimental

Aircraft, so I have a lot more leeway in my decision making.

The engine is all packaged up and put away on the shelves to make room

for the IO-360 that should arrive for teardown this weekend.

Despite decent compressions, this engine has always had a high oil

consumption (1 qt to 4 hrs) and the oil would turn very dark within an

hour or two of oil change. When I opened it up, this engine was

filthy inside. Not sludge, but just a dirty grime that seems to

be baked into the porous cast aluminum surfaces. My expectation

is that it is from excessive blow by in the exhaust valve guides, but I

haven't pulled any valves yet to confirm. But the insides of this

engine was thoroughly coated with a layer of black grunge that had to

be buffed off with a wire brush.

Update. The valves had some corrosion in the faces as did the

seats. That all ground out just fine. The valves and guides

all met new spec, so weren't replaced. The cylinders showed some

significant

corrosion pitting in the lower part of the cylinders and were honed to

clean them up. I suspect the pitting in the cylinders was leading

to significant blow-by causing the high oil consumption and the filthy

oil and interior.

11/21/2024 - After spending the last few days tearing down, cleaning and packaging up an IO-360 from another plane, I'm back to my engine again.

The crank journals measured to new spec and looked to be in really good

shape. There was some minor corrosion pitting, but it mostly

disappeared when I polished the crank. After discussion with

another mechanic with 50+ years in the overhaul business, we agreed that

the pitting found was inconsequential, so chose to polish the crank and

re-run it as it is.

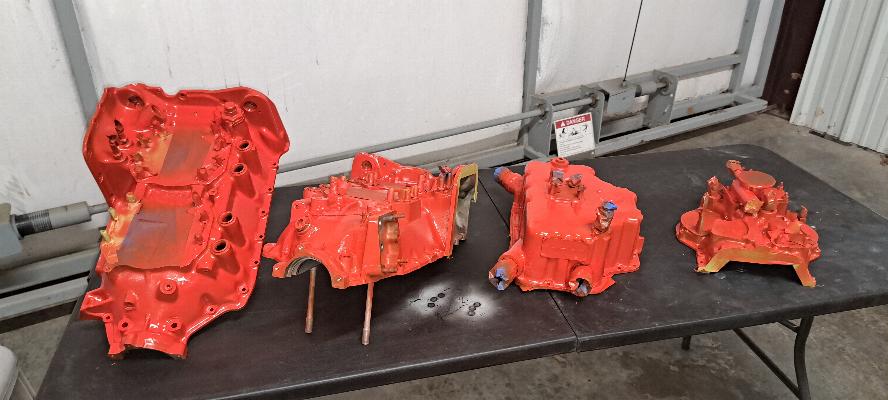

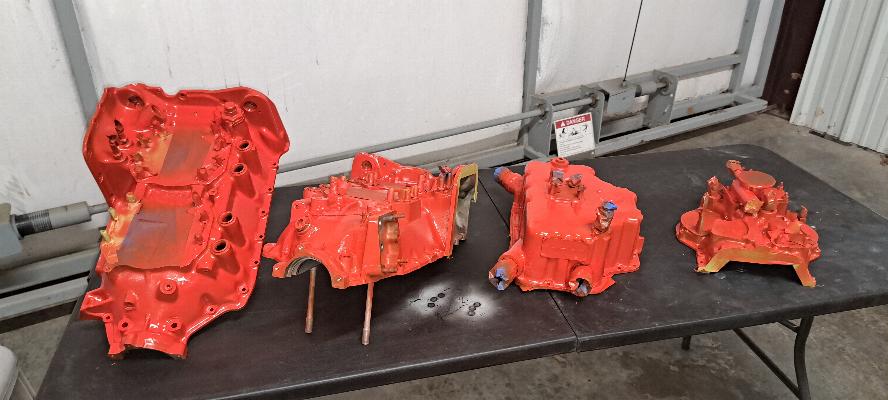

I got the case halves, oil pan, and accessory case out and cleaned on

them a bit more, then masked and painted orange to go with the Orange

Crush paint scheme that I'll be keeping on the plane.

I also have 4 new Superior cylinders ready to go along with 10:1 compression pistons from Combustion Technologies.

Case parts after painting along with freshly painted intake tubes and

pushrod tubes. I'm still waiting for my connecting rods and wrist

pins to be delivered, otherwise I'm ready to start going together with

the engine. I'll have to get pictures later, but I also pulled

the plug out of the crank and did the Lycoming SB505 inspection.

I don't think that had ever been done as it must have had close

to 3/8" of sludge in the front of the crank. I'll go ahead and

treat the crank bore with a Urethane metal primer per SI-505 before I

install the crank.

11/24/2024 - Lycoming SI-505 compliance... sort of. This was

under the old FAA A.D. 98-02-08. It had clearly never been

accomplished as I found about 3/8" of sludge coating the inside of the

crank bore. The AD requires pulling the front plug out of the

crankshaft. I do this by drilling the plug and running a sheet

metal screw through the plug, then attach to the plug with a slide

hammer. It comes out relatively easy. Once the plug is out,

scrape all the compacted sludge out of the crank bore. Since this

crankshaft is out on the bench, I was able to clean it thoroughly using

cleaners I would not have normallly put into an engine that was

assembled. Upon inspectiong, I found no pitting inside the crank

bore. These bores are pretty rough from the original tooling from

boring, but there was no pitting.

An interesting side note: This crankshaft was once used with a constant

speed prop. Typically for a fixed pitch prop, the plug in the

back of the crank bore is missing. That plug is only there if the

engine is going to be used with a constant speed prop. When

converting it for use with a fixed pitch prop, a hole is drilled in the

plug, then a plug is staked into the front of the crank bore. The

early 180 hp Mooney's used the carburated O-360-A1A, so it is likely

this engine was once flying around on the front of a Mooney M20C.

For those not familiar with how a constant speed prop is

controlled, the oil tube you see inside the prop bore has a hole

slotted into the side of the tube. The prop governor transfers

oil under pressure to the center of the front main bearing between the

two bearing supports where the crank rides. That oil flows

through the holes in the crankshaft into this tube and fills the bore

of the crankshaft with oil. That oil is pressurized to force oil

pressure into the prop hub to increase the pitch of the propeller.

The oil pressure is allowed to bleed off by the prop governor to

reduce the pitch of the prop. The constant speed propellor hub

slides into the front bore of the crankshaft with an O ring in a groove

on the prop hub to seal the prop hub to the front bore in the

crankshaft.

The Service Instruction calls for coating the inside of the crank bore

with Urethabond 104, which is a urethane based metal primer. I

was going to order some, but found it cost roughly $170 for a cup.

So, I looked up an equivalent Urethane primer. In this

case, I bought Devcon FL-10, which is chemically equivalent and cost

$42 per cup. OK, call me cheap. This crankshaft will never

be used in a certificated aircraft, so as an Experimental, it is my

option to treat the crank as I see fit. I am more concerned about

ensuring the crankshaft remains unpitted than I am with complying with

the specifications of the A.D. This morning I cleaned the crank

bore again, then acid etched it to prepare the surface to bond to the

Urethane primer. Once it was dry, I coated the inside of the bore

using an acid brush. The Service Instruction only calls for coating

the front 3-1/2" of the crankshaft bore. Typically in a machine

shop, the crankshaft would also undergo a magnaflux inspection for

cracks and a zyglow inspection for a better view of any potential

pitting.

I do have the capability of doing flourescent dye penetrant

testing, but my concern was not really with cracks as this crank had

not suffered any potential damage, and a visual inspection with

magnifier and a bright light showed no signs of corrosion or pitting.

My concern was for inspection for corrosion, then corrosion

proofing the crank bore. So, technically, I did not comply with

SI-505 as far as the sealing of the crankshaft goes when the crankshaft

is overhauled. I also did not overhaul the crankshaft. I

did perform a field cleaning and inspection, which is the part requred

while the engine is in service, then coated the inside bore to seal the

crank to prevent any future corrosion. This process would not be

acceptable for a certificated aircraft, but again, this crankshaft will

never be used in a certificated aircraft.

New plug placed into the front of the crankshaft bore. There is

some sealant painted on the inside of the bore around the shoulder

where the plug seats.

Then the plug gets staked with a hammer and punch. Punching in

the center of the convex plug will expand the plug out against the

edges of the crank bore and will hold it in place. I know

Lycoming has a special tool for this. But I've never seen one

fail that was properly staked. I have had one leak that I didn't

punch deep enough to get it to seal.

11/25/2024 - Getting the parts laid out to start putting my O-360-A1A

back together again. New bearings in the case. New camshaft

in the wrapper laying between the case halves. I'm flying off to

meet friends for breakfast tomorrow, so will get started on assembly

tomorrow afternoon.

11/26/2024 - I took the morning off and flew to Kingsley in Missouri for

breakfast at the Hangar Restaurant with some friends. Back to it

this afternoon. This photo is installation of the one piece front

seal. I removed the garter spring from the seal and clipped it

back together behind the prop flange, then heated the seal in a cup of

water in the microwave. It was boiling pretty good after 4

minutes, so I stretched it out over the flange using 4 motorcycle tire

spoons. Once it is over the flange, it will shrink right back to

size and you pop the spring into the back side of the seal. I

have done this countless times. It is always a struggle and I am

amazed every time that I can get it done without destroying the seal.

Bottom end of the engine together. The case is just bolted

together with the perimeter bolts snugged up. I'll torque them

all tomorrow. I forgot to install the front plug in the

crankshaft, so might want to take it back off the stand to install that

tomorrow before the engine starts getting too heavy for me to handle by

myself. I try to remember to take pictures as I put things

together, but keep forgetting. I'll get things done, then

suddenly realize that I forgot again to take any photos. (I have things

out of order here as I took the engine off the stand and installed the

plug in the front seen in the photos above.)

11/27/2024 - This morning I spent a lot of time moving all the engine

parts from the other hangar back to this hangar, then sorting and

cleaning parts getting them ready for installation. I also

checked the accuracy of my torque wrenches, then torqued the case

bolts, the front collar of the case, and the back stud that's hidden

under the cam gear.

Here, I have the connecting rods laid out with new rod bolts and rod

nuts. They are expensive, but you NEVER re-use rod bolts or nuts

in an aircraft engine. I have also cleaned and tested the hydraulic units for

the lifters and the cups that hold the end of the pushrods as you can

see here in the photo.

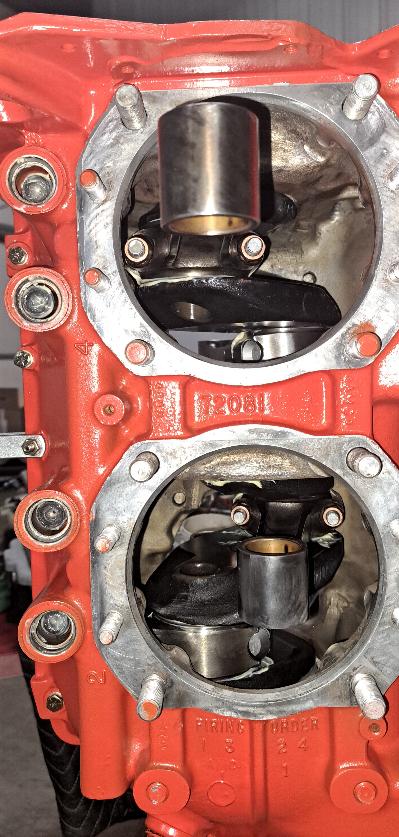

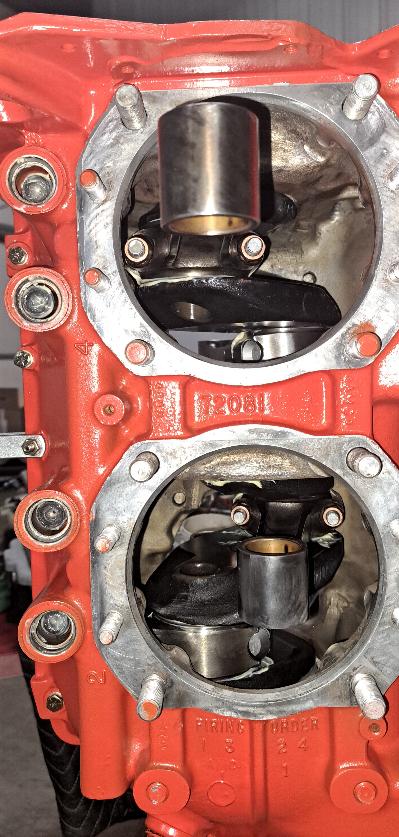

Rods are installed and torqued. If you look into the pushrod

holes, you'll see the cup there on top of the hydraulic units inside

the cam followers, so that part is all together now.

Pistons with rings installed, wrist pins, and the aluminum end plugs

for the wrist pins all ready for installation. This was supposed

to be a perfectly matched set, but you can see they sent me one piston

that is one gram heavier than the two on the right, and another piston

that is two grams heavier. I'll pair the two 1236 gram pistons

together for cylinders 1 & 2, then I took a gram of aluminum off

the boss of the heaviest piston to match the two on the left at 1237

grams to be pairs in cylinders 3 & 4.

New Superior cylinders ready for installation. I cleaned the

cylinders, then greased them thoroughly with Lubriplate Assembly

Lube.Everything that goes in the engine gets a thorough coating of

assembly lube. The only thing that gets a different treatment is

the face of the cam tappets and the camshaft lobes. They get a

coating of black moly grease with zinc to facilitate break in.

Tomorrow is Thanksgiving. I'll take the day to enjoy at home with

Becky while we snooze through some football games and perhaps give thanks

for all the ways we have been so richly blessed in this life. On Friday,

everything is set to install cylinders and continue the build.

I'm ready to get on with it.

11/29/2024 - Hanging the cylinders on the engine. The top left of

the engine is #3 piston all greased up with assembly lube and my ring

compressor clamped around it, ready to slide the cylinder over the

pistons and rings.

All 4 cylinders mounted.

Bottom side. I torqued all the cylinders down here before I

started putting parts on the bottom and all the cylinder base nuts were

easily accessible. FWIW, I go around and check the torque on all

the studs and especially the through bolts 3 times to ensure everything

is torqued correctly. Usually there is some movement; especially

on the throughbolts. It is imperative that they are torqued

correctly.

These are the cylinder base wrenches used to access these nuts.

The top of the wrench has a 1/2" square hole for a 1/2" drive torque

wrench to fit onto them.

Painted and installed the intercylinder baffles. These are

necessary to force cooling air around the bottom of the cylinders for

proper cooling.

Bottom side with the intercylinder baffles installed.

Top side with the baffles in. Also the pushrod tubes are now installed on the top side of the engine.

Setting the cam timing. On a Lycoming, there is an idler gear

that sits between the crankshaft (the small gear in the middle) and the

camshaft (the new copper colored gear at the top). Look closely

and you can see timing marks on all of them. The idler in

between has a lobe that bumps the fuel pump and also drives the left

magneto. The idler below drives the right magneto and the prop

governor. This engine doesn't have a prop governor drive installed. It is probably worth noting that all

these gears will get packed with assembly lube before the accessory

case goes on.

Nice, shiny, new cylinder heads ready for the pushrods and rockers.

This photo also shows the pushrod tube retainers in place.

Also note the cap on the exhaust valves. These are rotator

caps that are supposed to ensure that the valves rotate just a little

bit every time the rocker pushes the valve open. Most Lycoming

engines only have them on the exhaust valves. Some have none.

And the angle valve engines have them on both intake and exhaust.

Rockers and pushrods installed. It's probalby worth noting that I

use an air gun to blow some assembly lube down onto the valve stems as

well. They would be fine without it, but I like to ensure

everything is coated just in case the engine ends up sitting for an

extended period of time before use. It happens a lot more often

then I would like to think. Had this been done when this engine

was originally overhauled, it wouldn't have been a rusted up bucket of

parts when the builder finally started flying the plane.

Drain tubes that drain the oil from the heads back to the sump installed.

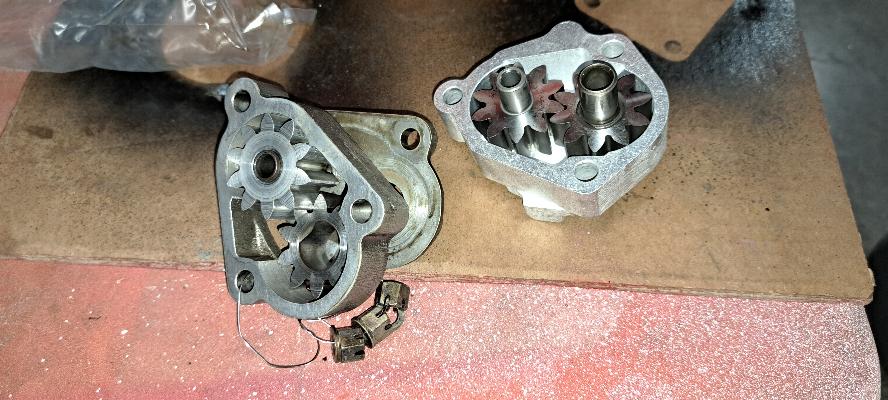

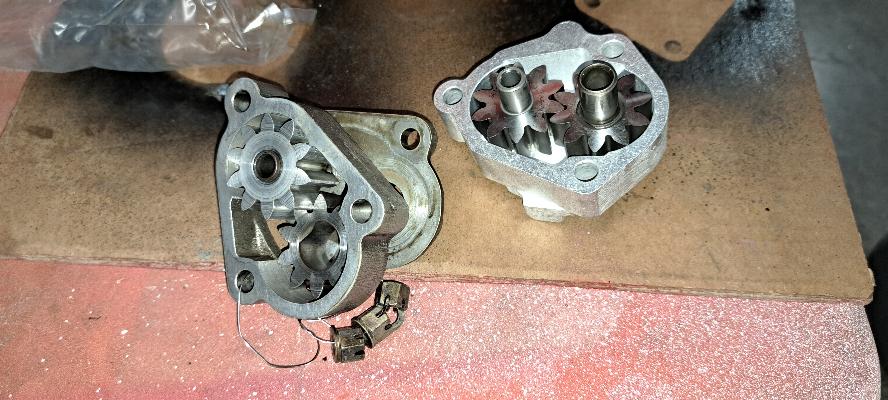

Here's where things came to a screeching halt. Old oil pump gears

at the bottom of the photo and new gears above. The old gears

rode on a

shaft that is pinned into a two piece oil pump housing. The new

gears have the shaft as part of one gear. That doesn't work with

the old housing and I didn't order the new one piece housing.

I placed an order for it late today, but doubt it will ship before

Monday. So, I can't do anything more with the accessory case

until I get the rest of the oil pump; maybe on Wednesday. The old

gears were in good shape, but were being replaced for an old A.D that

dates back to the 1990s that had never been complied with.

Next problem. I bought a set of used Slick magnetos from a RV

owner that was upgrading to Pmags. Both magnetos are impulse

coupled, which requires a spacer to be placed under the magneto to make

room for the impulse coupler. Since he was swapping to Pmags, he

even sent me the longer studs to accommodate the spacer.

Previously, only the left mag was coupled, so I needed the longer

studs and spacer for the new right magneto. I turned my old studs

out (the shorter stud in the photo above), then attempted to screw in

the longer stud. No go! He likely didn't know, but he had

oversized studs. They are a 5/16-18 thread, but are a few

thousandths larger to fit a worn out hole. Mine aren't worn, so

even after running a die over the threads several times, they are

still too big to fit into my 5/16-18 holes. I ordered new studs.

Of course these can be installed after the engine is assembled,

but will be a few days before I get them. So, Monday and Tuesday

of next week will be a time for cleaning and painting a few more parts,

and maybe get in some flying time in the other planes.

12/2/2024 - Not much to show today. I cleaned and painted

these parts. Two magneto spacers so I can install inpulse coupled

magnetos on both sides of the engine, a cover for the prop governor

accessory drive and the ring gear support. I found that the

gasket for the prop governor accessory drive cover was missing from the

overhaul kit as well as both magneto spacer gaskets and one magneto

gasket. I had spares on hand for all but the prop governor cover.

It was only $1.60 and free shipping, so not really worth trying

to battle my way through a warranty issue for the gasket set. For

some reason, they did include two sets of exhaust gaskets in the

overhaul kit. These are the expensive blow proof gaskets, so I

guess I came out OK on it anyway. I'll use them at some point in

time, although it's more likely that I'll just give them away when

someone is in need. The kit also included silicone valve cover

gaskets, but they are very thin as compared to the good ones that don't

leak. I was going to re-use the ones that were on the engine, but

found they were a bit deformed from decades of use and decided to try

the thin ones. I can always replace them if they leak.

I can't really move forward until I get the oil pump housing. I

am also waiting for the prop governor accessory drive cover gasket and

a pair of long magneto studs, but can install them anytime after the

engine is assembled. Hopefully the oil pump housing will arrive

shortly.

12/2/2024 - Quiet day while still waiting for parts. I lifted the engine off

the stand and installed the ring gear on the hub. I need the

timing marks on the ring gear to time the magnetos to the engine

after I install the accessory case. I also installed the new

valve covers. FedEx says the oil pump housing should arrive

tomorrow, so hopefully I can get the oil pump assembled and the

accessory housing on the engine tomorrow. I did repair a broken

brace inside the cowling you see standing on it's nose in the

background of this photo. A little bit of cutting, filing,

bending, drilling and riveting to repair the brace, but I failed to

take any photos.

12/05/2024 - The oil pump housing was finally delivered. You can see

in this photo the new housing is one piece and the old one is two

pieces. The old housing has the pinion for the upper gear pinned into

the housing while the new housing has a simple hole machined and the

pinion shaft is part of the gear. At any rate, the parts are incompatible

with each other and there is an old A.D. against the old oil pump gear

set with one aluminum gear and one scintered gear. It had to be

changed.

Oil pump mounted in the accessory case. Interestingly enough, the oil

splash shield mounted at the top of the case goes around the slinger on

the old camshaft. The new style camshaft has the gear as part of the

cam and the back side of the gear extends further back into the case.

This splash shield does not fit over the new gear, so I drilled the

two rivets out of the case and removed it. The newer cases have a

smaller splash shield that goes inside the cam gear. I have no way to

even acquire that splash shield short of buying another accessory case.

At worst the splash shield missing could potentially cause a leaky

tach drive. I'm already switching over to an electronic tach during

this update and am moving the mechanical tach to the front seat and

eliminating the old electronic tach that was in the front seat. If the

tach drive leaks, I'll switch back to the electronic tach for the front

seat and will put a sealed cap on the tach drive.

Looking

up into the accessory housing after it has been mounted. The

laminated

arm sticking down from the top of the photo is the fuel pump arm.

The big hole at the top of the picture is the oil suction tube

that is machined into the accessory case and oil tank.

Intake manifolds and oil filler/dipstick mounted. It's also worth

noting that I found the oil drain tube from the rocker boxes was going

to chafe on the intercylinder baffles on both sides. So, I

installed a piece of tubing over the drain tube to pad it from the

(white) baffle.

Top

side. I am missing the long studs for mounting the impulse coupled

right side magneto. I bought a used set of mags for the plane and had

two impulse coupled mags. Not a problem. I just have to install

longer studs and a spacer to accommodate it. The mags came with the

longer studs, but they were oversized studs and don't fit my case as my

holes are still pristine. I ordered new studs today, so won't have

them until next week. I'll move on to other projects for a few days,

then will get back to mounting the magnetos, then will mount the engine

back onto the airframe after the studs arrive, probably early to mid

week next week.

Left magneto sitting in place and and the spacer and gasket in

place

for the right mag. Normally, only the left mag has an impulse

coupler, so the spacer is not used on the right mag. However, the

used set I bought had an impulse on both mags, so I needed the spacer

for both mags to accommodate the impulse couplers. Also note that

the new studs are finally here and installed with the magneto spacer

mounted onto them.

The engine is set at 25° BTDC on the photo below, and the magneto

is inserted with the timing pin in place (timing pin is in the right

mag in this photo). In this case it is in the hole marked with an

"L" as both magnetors have a left hand rotation. Installing the

magneto in this manner has the mag at the firing point for #1 cylinder

and the engine set at the firing point for #1 cylinder. All

that's left to do is fine tune the timing with an inductive timing

tool. (magneto tweeter)

The 25° timing mark is lines up with the top seam in the case.

There are also marks on the front side of the ring gear that align

with a timing mark on the starter drive.

Magneto synchronizer hooked up to the magnetos. Since neither mag

is fastened down tight, in order to ensure a solid ground for timing

purposes, I have a ground jumper (the red wire) running between the

mags to ensure they are both grounded back to the synchronizer.

In this picture, you can see that both lights are on, indicating

the points are open. I have them synced perfectly together so

when I slowly rotate the engine, both lights come on together.

Note that the clamps are on the magneto bases now and they are

locked down in place.

12/10/2024 - New engine mount bushings. The old ones look really

tired and have been in service for over 40 years. The old ones

are Lord mounts. The new ones are Barry mounts. I don't see

any difference. However, the Lord mounts are priced at $250 each,

and the Barry mounts were $156 each. That's a significant

difference for the same product.

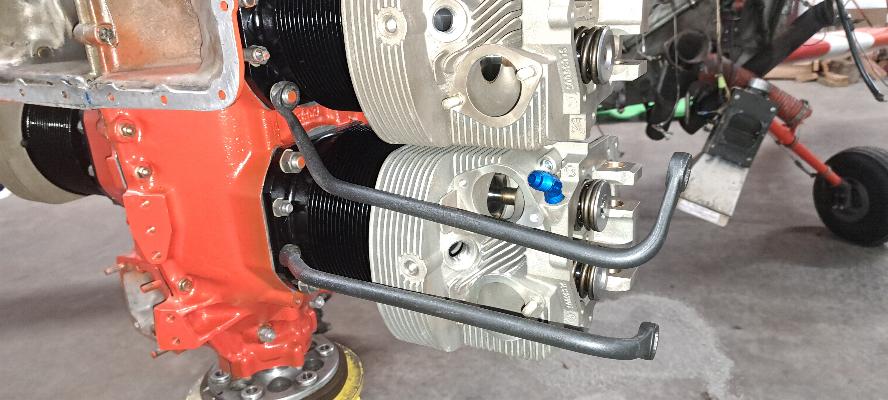

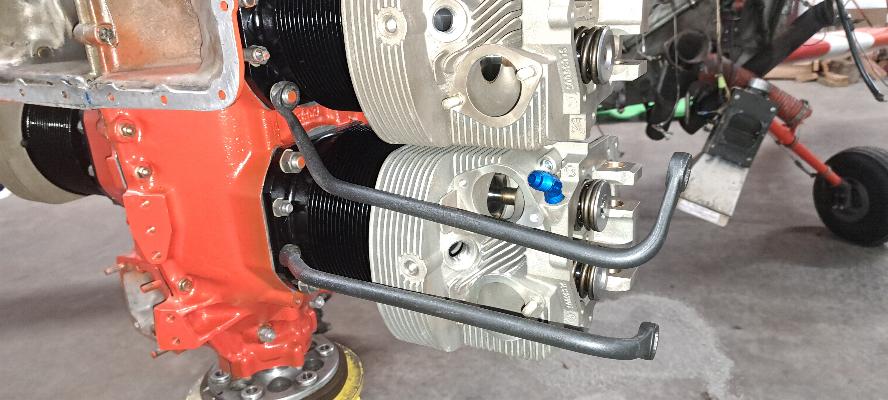

Ah, it's nice to see the engine mounted back onto the airframe. I

still have some assembly to do on the engine (carburetor, starter,

alternator and exhaust), then will start integrating the engine monitor

into the engine and airframe. Too bad the airframe is still

several months from flying. I didn't take another photo but did

get mount the primer lines and routed a few wires before I called it a

day.

12/11/2024 - This photo doesn't look much different except in the

details. The headers are on the engine after being drilled

and exhaust Gas Temperature (EGT) thermocouples installed. Also

there are thermocouples screwed into the cylinder heads for Cylinder

Head Temperatures (CHT), a thermocouple screwed into the carburator for

Carb Throat Temperature (carb ice detection), and another screwed into

the oil filter

adapter for Oil temperature. There is one more for outside air

temp that will eventually be mounted to an external panel. On the

lower right of the photo, the red box is the fuel flow transducer, and

behind the engine are the Fuel, Oil, and Manifold Pressure transducers.

All of this will be integrated into three cables that go to an

intermediate box that will talk via a serial cable to the engine monitor

I am installing in the cockpit. The monitor will also be

connected to the magnetos to sense RPM. If you did your math,

this adds up to 16 gauges that are all monitored and displayed on that

one 3-1/8" instrument. Additionally, it also calculates fuel

usage based on fuel flow and percent power based on Manifold Pressure

and RPM. I have the same instrument installed in my RV-6 and

really like it.

12/12/2024 - Today was mostly about fabricating new hoses for the fuel

system. This is a photo of the mandrel in use driving the

inner

part of the fitting into the steel braid hose. Yes,

the hose is contains a steel braid and with neoprene on the

inside, another layer or neoprene outside of the steel braid, then a

cotton braided outer cover. It is very stiff, but flexible.

These hoses needed to be made up to do the additional routing of

the fuel system to include the fuel flow transducer.

All the hoses with blue firesleeve are new. Starting at the lower

corner of the photo, the hose runs from the fuel shutoff valve to the

electric fuel pump. Next to the electric fuel pump is the

gascolator (water separator and fuel screen). From the gascolator

there is an orange firesleeve hose that runs to the mechanical fuel

pump. The output of the mechanical fuel pump runs up to the red

block hiding behind the engine mount at the firewall that is the fuel flow transducer.

From the fuel flow transducer, the line runs down to the

carburetor fuel inlet underneath the engine.

12/18/2024 - I've got the cooling baffling, spark plugs, and ignition

leads installed now as well as all the thermocouples, transducers and

wiring to feed the CGR-30R engine monitor. Also the carb and

airbox are now installed.

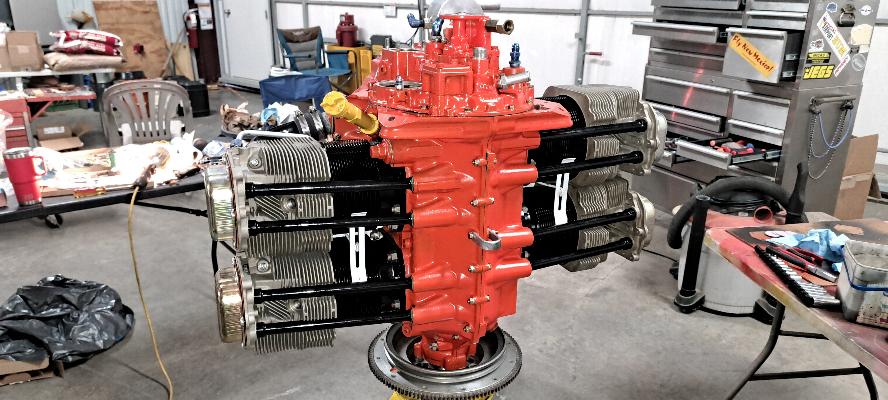

12/22/2024 - The engine is complete and ready for

the cowling, which is months away.

Why was this engine that had always been in Chandler AZ so rusty inside???

I spent some time digging through the logs to try to understand why

this engine had so much internal corrosion despite coming from a dry

climate. From the logs, here's the story with some speculation on my

part to fill in the blanks:

This engine was last overhauled in

January 1969. Here we are almost 56 years later tearing it down,

not because it leaks oil or runs poorly, but due to oil consumption and

a couple of cylinders just starting to get soft on compression. That's

actually pretty good service from an engine that was never started

until it was already a hot mess of corrosion and past calender TBO. The first engine run

following the 1969 overhaul was in 1981.

Apparently the owner purchased the overhauled engine for the Biplane project

he

was building, and it sat in his garage until it was ready to use.

Scratch building a large biplane is a daunting task and very time

consuming. It takes many years to bring that dream to fruition.

Now,

one would expect that since this was in Chandler, AZ, it would be

considered to be dry storage. However, even in AZ, there is

moisture,

and frost during the winter. I would guess it was in a cold

garage (or hangar) and

with the hot/cold cycles of the days and nights during the winter, it

was enough to produce some condensation in the engine.

Consequently,

there was some pitting on the crankshaft, rust on the camshaft, rust on

the cam tappets, and significant amounts of rust in the lower part of

the cylinder bores. The engine had definitely not been pickled,

nor

had it been properly assembled with assembly lube. Likely

they followed the manual and assembled the engine with engine oil.

That

works great if the engine is going to be put in service right away. But

if

it is going to sit, it needs a thorough coating of assembly lube on

everything steel, and or it must be pickled using a tacky fogging oil

before storage; or both! To it's credit, despite significant corrosion

on the

tappets, camshaft and cylinder bores, the engine had run 350 hours and

was still

running strong. The top of the intake lobes were starting to

deteriorate, but it would take another few hundred hours for that to

make a significant impact to the performance of the engine. I

mainly

tore into the engine due to the higher than normal oil consumption and

waning compression on one or two cylinders.

The oil consumption was likely due to the pitting in the

cylinders and the compression issues were due to corrosion on the valve

seats from before it was ever started. I installed new Superior cylinders, but the old ones

have since been honed to clean them up, valves and seats ground and are

in serviceable condition meeting specs. -Jeff