2024 - 2025 Electrical/Instrumentation Modifications

Engine overhaul

Electronics/Electrical

Fuel System

Trim System

Fabric Recover

Item #6 from the Rebuild page:

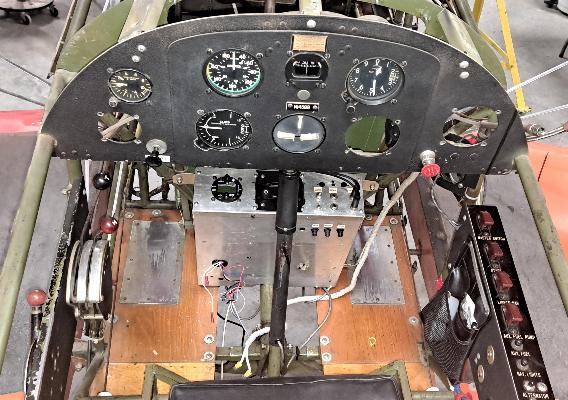

The rear cockpit is a hodge-podge of instruments and radios

mounted whereever they could be fitted with little regard to ergonomics

or visual scan. I don't know that I'll straighten it all out, but

I have purchased and Electronics International CGR-30 to consolidate

all the engine instrumentation.

11/13/2024 - Well now she's looking kind of naked. All the sides,

top deck and belly skins are removed. They will all need to be

cleaned and repainted, but having them off will also give me much

better access to the instrument panel, plumbing, and wiring as I change

much of it.

12/7/2027 - Pearl Harbor Day - While I wait for a few minor parts for

the engine, I started cleaning up the rear cockpit. The first

thing was to remove the instruments that will be replaced by the new

engine monitor. Several old instruments will come out of the

panel, and the bottom subpanel that's between my knees will go away all

together. I'll still need the forward part of the subpanel for

the radio and transponder, but the rest is being removed.

Lots of other changes as well. The control stick heads will be

replaced with new handles that will include integrated trim and PTT

buttons. The elevator trim control (the Red knob) at the lower

left of the photo will be removed. I may rearrange the switch

panel on the right side as it is a bulky and inefficient layout.

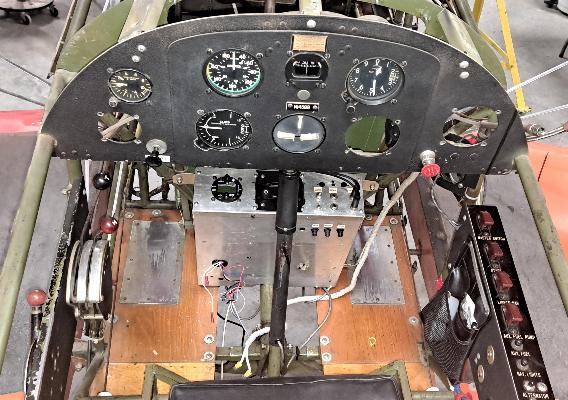

This is the front cockpit. There aren't going to be any major

changes here. The electronic tachometer at the right side of the

panel is inaccurate, so the old mechanical tach from the rear seat will

be moving to the front cockpit to replace it. The engine monitor

going in the rear panel will have the tachometer integrated as part of

the monitor. The pipes and hoses running along the right side of

the cockpit are being removed as they are there for Mechanical Oil

Pressure, Fuel Pressure and Manifold Pressure gauges. Those will

be replaced by electronic transducers mounted at the firewall and are

integraded as part of the engine monitor. The same is true for the

wiring from the CHT and EGT gauges as they will also be integrated as a

part of the engine monitor.

12/9/2024 - Here's all the stuff that came out of the rear cockpit so

far. The subpanel from between my knees is on the left.

Combination Oil Temp, Oil Pressure, Fuel Pressure gauge,

Tachometer, Manifold pressure, Ammeter, Exhaust Gas Temperature, and

dual Cylinder Heat Temperature gauges. All of these work and have

the thermocouples and all but the tach are up for grabs if you need

something. The electronic tach from the front cockpit will also

be up for grabs.

12/11/2024 - Building a new switch panel. This one was kind of

neat with military type covers over the switches. But the switch

covers are largely unnecessary and the switches are so spread out down

this panel that it takes too much room. I don't like reaching

back behind my elbow to reach switches. I'll build a new cover

for the panel and remount the switches in a much more compact design.

The panel that was under the plastic panel. All the switches and

breakers are still hooked up; just hanging below the panel. I'll

rearrange the wiring and switches when I get started mounting

everything into the new panel.

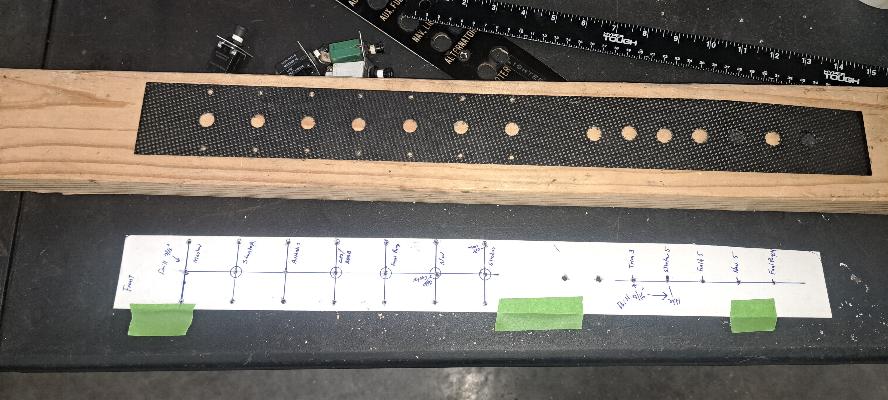

I'm going to fabricate a new cover from carbon fiber. This is a

simple wet layup of two pieces of carbon fiber on a waxed countertop

that I use for wet layups.

The layup is covered with peel ply (dacron fabric), then some felt to

absorb the excess resin, then vacuum bagged using a medical vacuum pump

and cheap painters masking plastic stuck to the board with the cheapest

caulking I could buy. It's cold in the hangar (roughly 55°

F), so that's my oil filled mini-heater set to blow onto the layup

overnight. It is set on low heat and is also thermostatically

controlled. Additionally, the warm exhaust from the cooling fan

on the vacuum pump is also blowing across the layup. Even using

West System Epoxy with the medium temp hardener for the layup and a bit

of heat, it will probably still take at least a couple of days to cure.

Before someone tells me I'm not supposed to do layups this cold,

it should be noted that this is NOT a structural layup. If it

was, I would not be doing this in the cold hangar.

Carbon fiber piece out of the vacuum bag and ready to be trimmed.

This will be a direct replacement for the panel above with a

different arrangement for the switches and breakers.

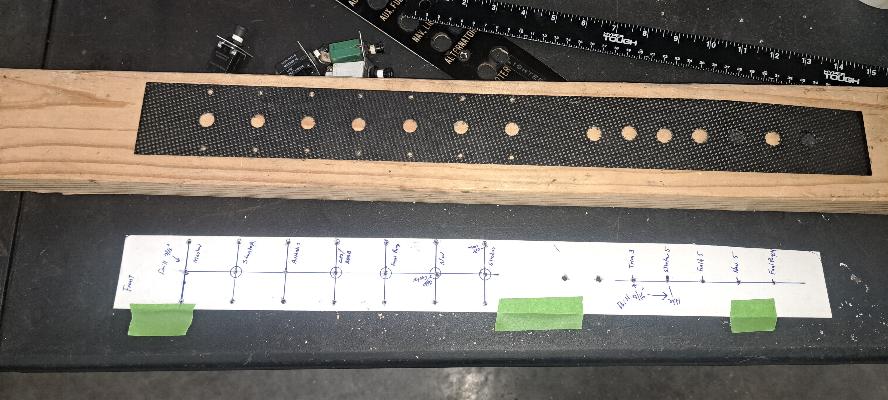

12/13/2024 - I created a new panel template, used it as a layout on the

old swiss cheese aluminum panel (see next photo) that was under

the plastic switch panel. Then I transferred the same hole

pattern to the

new carbon fiber panel.

New CF panel in place over the swiss cheese panel. The old switch

guards will be removed and most of the breakers will be replaces with

more compact breakers that I have on hand.

New pieces in the instrument panel so far. The white gauge on the

left lower part of the panel is the fuel gauge. Hopefully this

one will actually function in flight. The blank instrument

towards the lower right is the Electronics International, CGR-30P.

This is an all in one LED display engine monitor. I have

this installed in the RV and really like it. It offers a lot more

than I really need in this plane, but also allows me to consolidate a

bunch of engine instruments into one gauge that displays a bunch of

data, but also triggers both amber and red warning lights if something

gets out of spec with the engine.

12/12/2024 - Today was mostly about fabricating new hoses for the fuel

system. This is a photo of the mandrel in use driving the

inner

part of the fitting into the steel braid hose. Yes,

the hose is contains a steel braid and with neoprene on the

inside, another layer or neoprene outside of the steel braid, then a

cotton braided outer cover. It is very stiff, but flexible.

These hoses needed to be made up to do the additional routing of

the fuel system to include the fuel flow transducer.

All the hoses with blue firesleeve are new. Starting at the lower

corner of the photo, the hose runs from the fuel shutoff valve to the

electric fuel pump. Next to the electric fuel pump is the

gascolator (water separator and fuel screen). From the gascolator

there is an orange firesleeve hose that runs to the mechanical fuel

pump. The output of the mechanical fuel pump runs up to the red

block hiding behind the engine mount that is the fuel flow transducer.

From the fuel flow transducer, the line runs down to the

carburetor fuel inlet underneath the engine.

These transducers also get installed. The PT-100 is the Oil

Pressure transducer, The PT-30 is for fuel pressure, and the red block

is the fuel flow transducer. The gold colored transducer below is

the manifold pressure transducer.

I mounted the oil and fuel pressure transducers to the firewall (left),

the manifold pressure transducer (right), the fuel flow transducer (the

red block) and the EI data module (top center) to the

firewall. I had some of these mounted yesterday, then it occured

to me this morning that once the plane is back together, the nuts on

the back side of the firewall will not be accessible. So, I

spent the morning riveting nutplates into the firewall. All

these transducers feed data to the EI CGR-30R engine monitor

display.

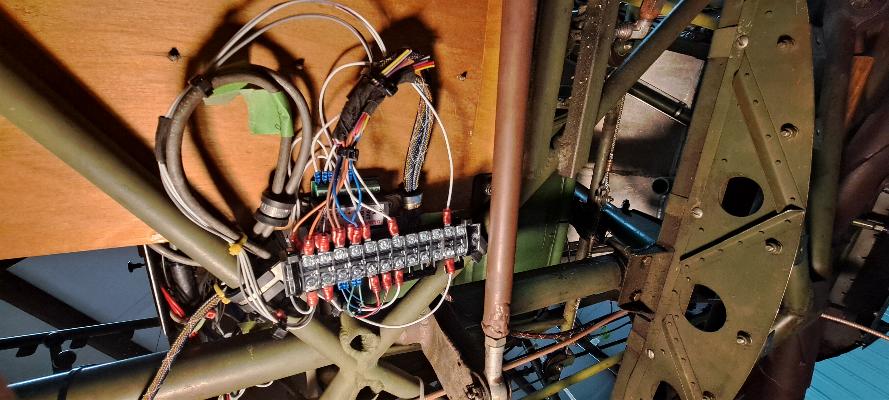

12/16/2024 - Today was about connecting and tidying up the wiring for

the engine monitor. All the brown wiring in the photos above and

below is Thermocouple wiring. 4 EGTs, 4 CHTs, Oil Temp, Outside

Air Temp, and Carb Inlet Temp. There are a couple of white wire

buncdles just behind the master relay on the near side of the firewall

that go to the Fuel Flow Transducer and Manifold Pressure Transducer.

In the photo below, you can see two black wire bundles that are

zip tied to the top of the firewall/engine mount that go to the Oil

Pressure and Fuel Pressure transducers.

I took advantage of existing holes in the firewall that used to house

pressure lines that are no longer needed to route excess wiring behind

the firewall where it is bundled, then enough wire pulled back through

the firewall to route around the engine as necessary. There is

still more wiring to pull, splice and mount for the engine monitor, but

this is the bulk of it. I do still need to pull a data line from

the data module to the display, and another line to monitor the

voltage. I need to find a place to install the shunt for the

ammeter and pull the wiring to the shunt. There is a bunch more

wiring work to do that I'm not quite ready for yet, so there's still

more to come on that.

This is the carbon fiber switch panel I fabricated. There are 7

switches and 5 breakers. In order the switches are Master,

Starter, Aux Fuel Pump, Avionics, ADSB/GPS/USB ports, Nav Lights, &

Strobes. I rearranged the layout and order of the switches, so

all the wiring below the switch panel is cut loose. Some wiring

will need to be added and some other wiring replaced. When

completed, it will all get zipped up tightly in place. I broke

the USB port for my GPS while pulling the wiring from it, so had to

order a replacement. It won't be in until this weekend.

12/17/2024 - Not much to show photo wise today. I have all the

switches and breakers in the right side console now. I still need

to tidy up the wiring a bit under the console and replaced the USB port

that I broke, otherwise it's done.

Small change to the front panel. Again, not much to show, but

took hours of fiddling around. The electric tach that was in the

right side of the cockpit was removed and the mechanical tach from the

back panel was to be installed. Then I had a small interference

problem where the angle drive on the back of the tachometer was going to

rub on one of the center section braces. No problem, I'll just

swap it with the airspeed indicator. Easier said than done.

Now I had some challenges with whether the new tach cable would

reach. It did with some different cable routing. Then the

pitot and static lines to the back of the Airspeed Indicator didn't

reach. I found that I had all the right stuff on hand to extend

or replace the lines as needed to make everything fit. But it

took a lot of fussing around and searching through my parts bins to get

it done.

12/18/2024 - Today I completed the switch and breaker mods to the side

panel and tidied up all the wiring. Below you can see the CGR-30R

Engine Monitor from Electronics International is finally lit up.

The 3-1/8" hole to the right with a square hole in the filler panel is

cut to fit the trim indicators. I'll be redesigning the trim

system and adding servo controlled trim tabs to the tail next.

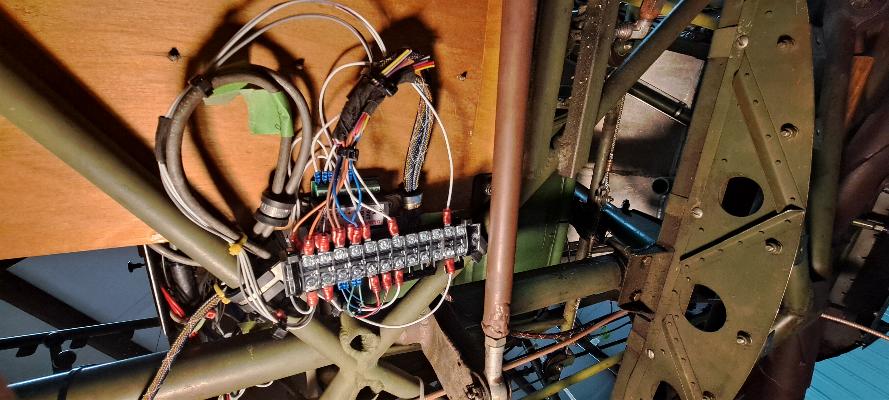

12/24/2024 -Christmas Eve... Today's goal was to wire in the

switches

for the new stick grips. The switches on the stick control

elevator

trim, radio transmit, and intercom transmit and all are active from

either seat. I decided to add a terminal block under the

right rear

floorboard along with the relay deck for the trim servos that came with

the stick grips to enable the trim servos to be controlled from either

seat. You can see the relay deck just under the wiring connected

to

the terminal block. I still need to pull a ground wire, +12V

wire, and

the two servo leads to complete this part of the installation. I

also

need to wire in the trim indicators in the instrument panel. I

failed

to take a photo, but today I also fabricated a new panel mount for

the trim indicators and painted it black. It will show up in

the next

round of wiring when I install the indicators. I'm waiting for

some

mini-Molex connectors to arrive to complete the connections, although I

can pull the wiring to the tail yet. The connectors should arrive

on Saturday.

12/26/2024 - The trim indicators are temporarily mounted in the left

side of the panel. I just need to replace the clecos with screws.

The terminal block under the floorboard is completed.

I'm waiting for crimp on ferrels for 24 gauge wire connectors and

mini-Molex connectors so I can complete the wiring for the elevator

trim servos. This stuff should all be here this weekend.

I started stripping the fabric from the aft fuselage so I could route and attach the wiring for the elevator trim.

12/29/2024 - The connectors I've been waiting on arrived in

yesterdays mail, so I've now completed all but the installation of the

fuel tank sending unit for the electrical/electronics work to be done

on the plane. Now I have the trim indicators mounted and lit up

on the right side of the panel. Compare this cockpit photo of the

finished rear cockpit to the photo below from before I started.

Also compart the switch/breaker panel on the right console to the finished panel below.