2024 - 2025 Fuel System Modifications

Engine overhaul

Electronics/Electrical

Fuel System

Trim System

Fabric Recover

Items #2 & #3 from the Rebuild page: Inadequate fuel

quantity. A thirsty O-360 with only 20 gallons of fuel doesn't

give a slow plane much range. I want to work out a design to add

some fuel to the upper center section.

Fuel quantity indicator. It had a float and stick indicator like

a Cub. That's fine if it works, but on this plane, the float hit

the back of the tank and the stick was not nearly deep enough to

measure the lower half of the tank. Not very useful if it only

measures the top half of the tank. I replaced that with a

hydrostatic fuel gauge that measures the head pressure of the fuel.

That worked fine on the ground, but as soon as I start the

engine, it would go full scaale to indicate full all the time. So, now I'm changing to a

float type fuel gauge.

12/18/2024 - Installed new fuel gauge in the panel.

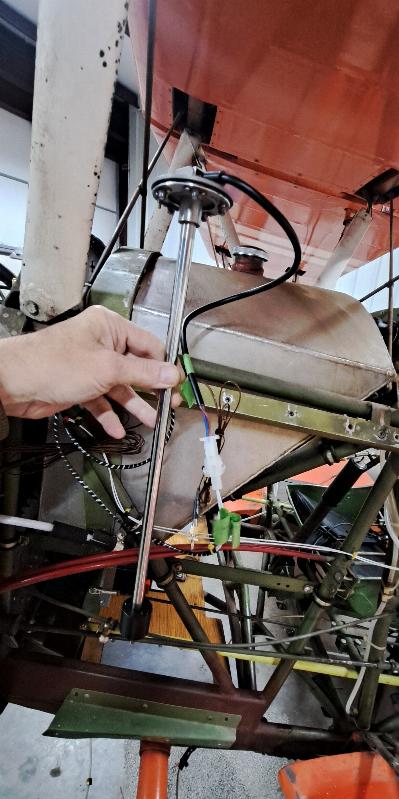

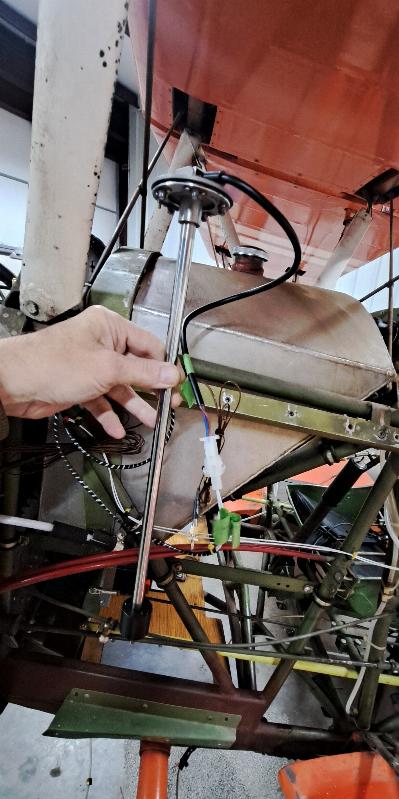

New float type sending unit to go into the tank with Molex connector for wiring.

This is currently the only fuel tank in the plane. It holds 20

gallons of fuel. With an O-360, that's 10 gallons/hour at cruise

in a plane that only cruises at roughly 100 kts. With a 30 minute

VFR reserve, that only gives me a 150 nautical mile range for

planned fuel stops, which is very limiting.

I'll need to cut a hole in the top of the tank to install this unit.

I fabricated the clamping flange you see screwed on in the photo above to go inside the tank to allow

me to clamp down onto the top. I'll seal it with some ProSeal

when it goes on. The one small cad plated screw in the clamping

plate is there to hold the plate up to the top of the tank while I

insert the unit into the tank and run in the rest of the mounting

screws. This may require a second screw and nut plate when I

install it. We shall see...

1/4/2025 - The fuselage tank is now out where I can work on it on the

table top. The line on the side is where there is an internal

edge at the bottom of the tank that I have to miss with the fuel probe,

so I need to be in front of that line. The line on the top of the tank

(see below) is where the limit of where the back edge of the hold down

strap will fit. I've got a pretty tight spot to fit this all in.

This is what is left of the backing flange I made to go inside the tank

to bolt the fuel probe into place. The small phillips screw at

the left holds the internal mounting flange up to the inside of the

tank so I can run in

the screws that clamp the probe down to the top of the tank.

Here's where I made a mistake that made things a bit more

difficult. When I cut this hole with my hole saw, I cut right

into a vertical divider that runs down the middle of the tank.

Oops! The divider is visible through the hole in the photo

above. That's why the hole all the way to the right is not

drilled yet and I had to cut down the backing flange. I cut

the backing flange to butt up against the internal bulkhead.

Since

there are two relatively thick layers of aluminum where the bulklhead

buts against the top of the tank, I drilled and tapped

the hole to the right through the tank and bulkhead and used that to

hold down the fifth screw rather

than a nut plate like the other 4 screws.

The backing flange is now mounted inside the tank with the countersunk

screw holding it in place under the mark where I have "Index" marked on

the top flange. All but the one screw all the way to the

right are run into nutplates that are riveted to the flange backing

plate that is inside the tank.

The screw on the far right side of the flange is threaded into

the top of the tank and the top of the internal baffle. It is all

sealed with a generous bead of ProSeal underneath and a finger fillet

of proseal around the flange from where it squeezed out.

This photo is looking down through the filler neck. You can see

the fuel probe just missing the back of the tank and just missing the

perforated bulkhead to the right. The black slider at the bottom

of the shaft is the float that floats up and down the shaft where it is

sensed to indicate the fuel level.

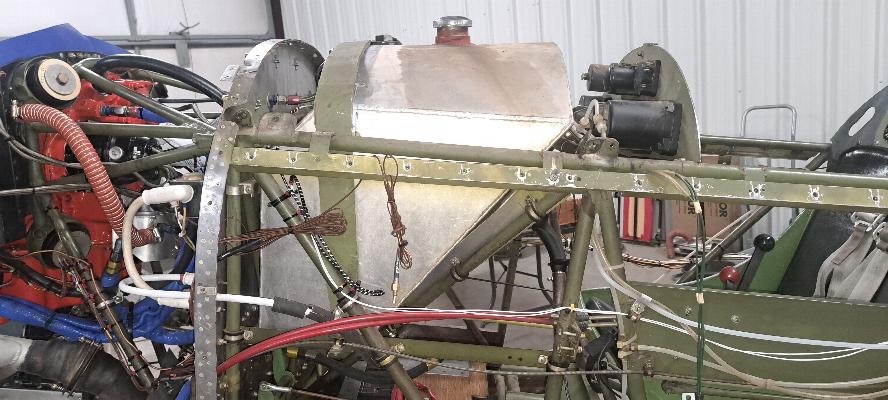

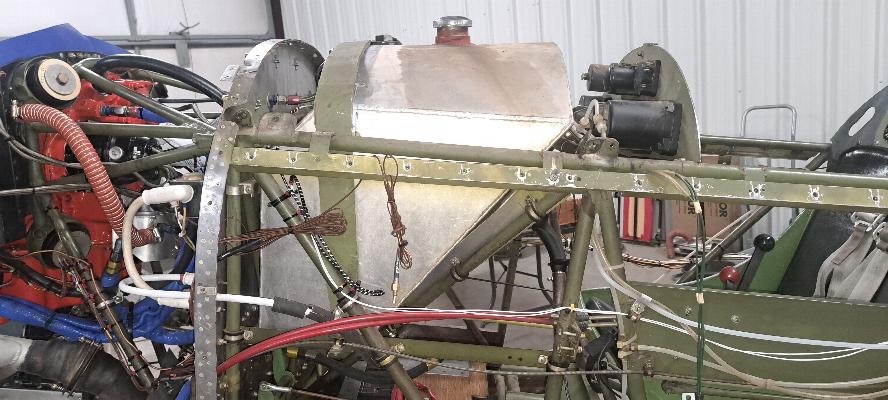

1/7/2025 - The main fuel tank is now re-installed in the airframe.

That's the first part to go back onto the plane that had been

removed, so is the first step towards reassembly. Only about

100,000 steps left to go! It is possible the bump on the top of

the fuel probe may interfere with the top of teh boot cowl. If I

does, I'll cut an access hole and raise the cover 1/8" to allow it

sufficient room.

The plan is to design and build an additional fuel tank into the upper

center section, then refuel the lower tank from the upper tank by

opening a valve to allow it to drain. I hope to get 8 - 10

gallons into the upper tank, which would extend my range by an hour;100

nautical miles. The volume will depend on how much room I can

find in the center section. It has cross braces that go through

the middle of the center section, so I need to either move the cross

braces and re-enforce the center section with plywood, or build some

custom tanks to fit around the cross braces and plumb them together.

I'm leaning away from doing structural modifications to an

aerobatic plane. I'm not an engineer and don't feel that I'm

qualified to analyse all the stresses the center section sees.

So, I'm leaning towards fabricating some custom shaped fuel cells

around the cross braces and plumbing them together. I'll start

developing a more mature plan once I have the center section off on the

bench and get the fabric off.

1/25/2025 - I spent about a month and a lot of $$ building a carbon

fiber/fiberglass tank with vinylester resin. I've done this

successfully before, but had some serious technical challenges in

fabricting the tank to bridge over the internal cross braces in the

center section. Ultimately, it leaked and was really

unrepairable. Bad design work on my part and poor construction

technique as well. I cut it all out and trashed it, then

moved on to another plan.

Repairing the center ribs and reinstalling them in the center section.

I left the reinfoced ribs that supported the tank in place for

the other two internal ribs. I would have had to destroy the ribs

to remove them. Not worth the effort to save a few onces.

1/28/2025 - I've not completely given up on the idea of an auxilary

tank. I'm considering building a tank inside the baggage

compartment shown above. I would only use the bottom 8" of the

baggage area, which would make an 8 gallon tank, leaving a small

baggage area above the tank. Additionally, I would add a bottom

and back into the turtle deck (shown below), then hinge the headrest at

the bottom for ready access, making for a second readily accessible

baggage compartment. I've not made a decision on this yet, but am

mulling it over.

3/6/2025 - After weeks of doing engine work for others, I'm back to my plane

again. I have made the decision to have a local welder weld an

aluminum tank for me. Why? There is a lot of uncertainty

about the future of 100LL, and the G100UL candidate to replace 100LL is

currently getting a lot of negative press regarding degredation of

paints and composite parts. With 10:1 pistons in the engine, this

plane will require 100 Octane fuel. So, to be on the safe side, I

made the decision to build the aux tank with welded 5052 aluminum.

The first thing to do was to consult with the local welder.

We agreed to fabricate this using a bottom plate of .063" that

will mount to the same tabs where the baggage compartment used to

mount. This bottom plate will become the mount for the tank.

The rest of the tank will be constructed using .040" 5052.

Interesting that I can order 2x3' sheets of 5052 on Amazon

relatively inexpensively.

The baggage box is now out of the airframe. Interesting that they

had to bend it to get it into place, then rivet the back of the box in

so it would retain it's shape.

This is where the baggage box used to be. The aux fuel tank will get mounted into here.

I started to install that little cutout under the left side of the

instrument panel as a place to mount a fuel gauge for the Aux Fuel

Tank. However, the carb heat cable was already kinked against a

tube with it mounted to the right of the current fuel gauge. With

the little mini-panel under the left side, there was a second kink in

the carb heat cable and that ruined the cable. I had a new cable

on the shelf, so moved the cable to the far left side of the panel to

eliminate one sharp turn in the cable. Then I did an offset grind

on two washers on either side of the panel so I could mount the cable

with the backside pointing downward a bit so I could eliminate the

sharp curves in the cable. It works better than ever now.

Next up was to fabricate a template for the floor of the new baggage

compartment. The way it fits, it will have to go in as two pieces.

I have the better part of a gallon of vinylester left over from the

previous attempt at building a fuel tank, so decided to use it with

carbon fiber to fabricate the floor and back of the baggage

compartment. VinylEster has a limited shelf life once it has been

promoted to be sold, so this stuff needed to be used anyway as it will go bad before summer. So,

I had the vacuum pump running much of this week while I fabricated

several small pieces from carbon fiber.

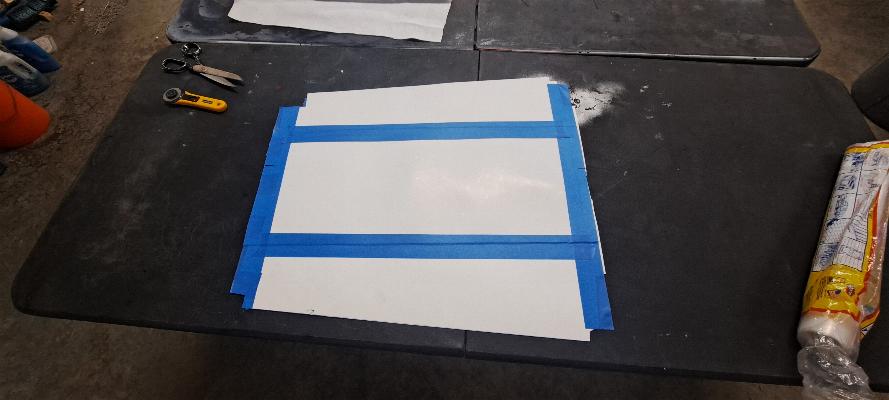

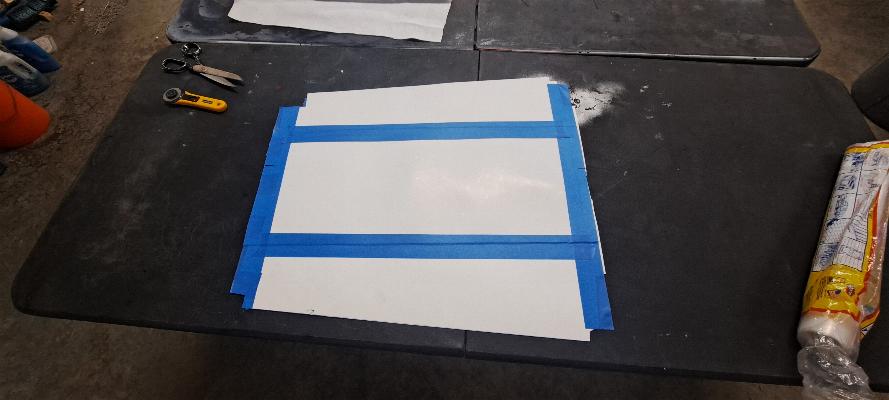

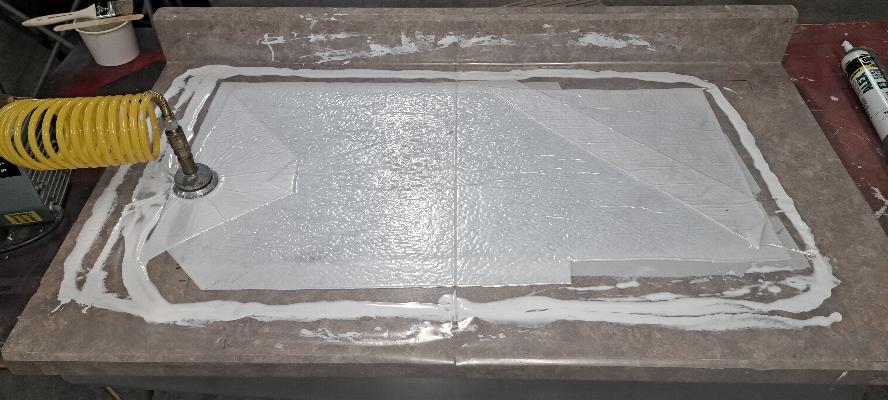

This is an example of how I do vacuum bagging if I am making flat

parts. I lay up the part on a piece of waxed formica countertop,

add a piece of peel ply (dacron fabric), then some felt to absorb

excess resin, then cover with plastic sheet cut from the cheap painters

plastic drop cloth you can buy at Walmart. Then I use the

cheapest caulking I can find and run a bead of caulking around the part

and slap the plastic down over it. Plug in the inexpensive

medical grade vacuum pump, let it cure and you have a vacuum bagged part.

Contoured or molded parts require some more expensive bagging materials,

but if I'm making a flat panel, there is no need to waste my money on

the expensive bagging materials.

This is the baggage compartment as fabricated. You can see the

seam of screws down the middle to hold the two halves of the bottom

together. They are also anchored together with some vinylester

resin as well. There is a black aluminum angle half way back in

the baggage compartment. I'll attach a baggage net to prevent

larger or heavier things in the baggage copartment from migrating to

the back of the compartment. Think in terms of what might happen

while going straight up in a hammer head. Everything in the

baggage is going to try to go to the back, then while coming straight

down, it might very well come slamming forward into the front of the

compartment. I want to keep a bit better control of the stuff in

there.

I peeled the upholstery of the old headrest off the aluminum plate it

was mounted to and bonded it to a plywood panel. That panel will

be hinged at the bottom with a piano hinge to tip the headrest forward

to access the baggage compartment. Previously it was bolted in

place. I added a carbon fiber panel to the bottom of the headrest

to close up the baggage compartment. The headrest isn't mounted

yet. Only the piano hinge is mounted to the airframe. The

rest is just sitting in place to see how it looks.

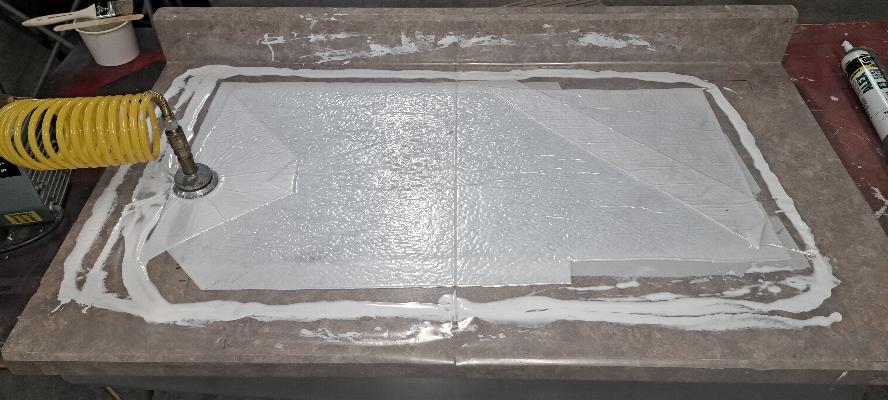

This is the .063" 5052 aluminum base for the fuel tank. I'll

mount it into the airframe and on the mounting tabs for the old baggage

compartment, then will build the rest of the tank onto this plate. The rest of the tank will be .040" 5052 Aluminum.

3/8/2025 - I completed cutting out the pieces to fabricate the fuel

tank. It's held together with masking tape for now, but all the

corners are tight enough that it shouldn't be a problem from the

welder. I have one welding flange with 1/8" NPT thread to go into

the bottom of the tank to be the fuel drain. I have another

flange with 1/8" NPT that goes in the top towards the front that will

be the tank overflow/vent, and another welding flange that goes towards

the back of the tank on the top for the fuel pickup. The big hole in the top is for the

filler neck. I don't have the fuel gauge transducer yet, so I

ordered a gasket for it that I'll use for a pattern to mark the tank

penetrations, then will rivet in the nut plates to mount the gauge.

The gauge won't be here until the end of the month, but once the

nut plates are installed, I can take this tank to the welder to be

completed.

You can see in the photo above that there is a substantial flange

around the bottom of the tank. The tank will be mounted by that

flange. However, I will also add some padded steel angle under

the tank to help support it.

Filler neck and two of the welding flanges.

Bonding the 3/8" fuel pickup tube into the bottom of a AN822-6D fitting

that is screwed into the 1/4" NPT thread in the welding flange.

3/9/2025 - Added the USB charger outlet and electronics into the

baggage bay. I have an Echo UAT ADSB In and Out unit, and a

Stratux ADSB receiver as a backup device.

The headrest is now attached to the piano hinge and closes off the

baggage access when it's up. I'll be adding a cabinet lock to it

to make the baggage area lockable.

3/13/2025 - Added new gauge for the aux fuel tank to the

lower left below the panel. I also added an indicator light just

above the gauge to indicate when the transfer pump is running to

transfer fuel to the main tank. I also installed the lock into

the headrest, but forgot to take a photo. I'll get that tomorrow.

3/15/2025 - I fabricated this mount to go under the new fuel tank.

The fuel tank is still with the welder. I'll check on it

Monday. The mount obviously will need to be primed.

3/18/2025 - Installed fuel transfer pump for the Aux Fuel Tank.

I'll start running the plumbing to the front tank tomorrow.

3/19/2025 - I routed the 3/8" aluminum fuel line from the fuel transfer

pump in the rear up to the top of the main fuel tank in the front.

In this photo, it is easily identified by the orange firesleeve

protecting the fuel line where it lays on the ongeron just in front of

the main fuel tank Below, the welder is slaving away melting

aluminum TIG welding the new aux fuel tank. Hopefully he can

finish it tomorrow so I can leak check it.

3/21/2025 - I got the fuel tank back from the welder this afternoon.

This is the leak test with it full of 100LL. It holds 9 gal

of fuel, which should extend my air fime from 1-1/2 hours to 2-1/2

hours plus VFR reserve. I should be able to go somewhere with it

now.

I had predrilled the bottom flange of the tank as well as the mounting

frame that's underneath to fit onto welded tabs in the fuselage.

All had been carefully fitted and fit perfectly. I failed

to remember how badly sheet metal, and even 4130 tubing distort from

the heat cycles of welding. When I tried to install it, nothing

fit. Not even close. I had to back up and redrill all of

the mounts, so it turned into a bit of a struggle, but I finally

prevailed late this afternoon. I still need to complete the

plumbing for the tank and it will be ready to go. Note the large

diameter flush mounted filler cap. It will be challenging, but

not impossible to refuel. Once the fuel system is completed, it

will be time to go full bore on the fabric work.

3/22/2025 - I installed the fuel pickup line, the overflow/vent line,

and the tank drain line today. I'm still missing a bunch of adel

clamps for the line running forward, and the two adapter fittings that

go on either side of the fuel pump. They should be delivered on

Monday.

3/24/2025 - I rolled the plane out for the first time since November.

The task here was to fill the Aux Fuel tank, then transfer the

fuel from the Aux Tank to the Main Tank to test the fuel transfer

system as well as time to transfer.

I started with the Aux tank full and the Main tank empty.

This also tested the fuel gauges in both tanks. Both gauges

appear to be reasonably accurate. For this picture, you can see

that I have transfered 1/4 of the Aux tank into the Main tank.

With the Aux tank holding 9 gallons and the Main 20 gallons,

these gauges appear to be just about right. The transfer time was

a bit disappointing. It took 25 minutes to transfer the 9 gallon

capacity of the Aux tank into the Main. However, that is still

more than twice the rate of fuel burn for the engine, so it's going to

have to be fast enough. I also noticed in the photos here that I

need to label the gauges as to which gauge is for which tank.