Lycoming IO-360-A1B6D overhaul due to cracked case.

This engine came from a Cessna Cardinal RG belonging to a friend.

I've flown this plane in the past. Nice plane and good

engine that had a little bit of a vibration in it. That was

compensated with a dynamic balance of the prop, but those stresses take

their toll. I can't say that was the cause, but the engine

started leaking oil through a stud on #1 cylinder. A shop in

Oregon investigated the oil leak for him and found the case was cracked

through the left lower stud. My friend removed the engine and

brought it to me. The engine is over 1000 hrs since overhaul and

has a pretty significant oil consumption even before it started leaking

oil. My recommendation was that as long as we have to pull

everything out of the case anyway, and it is clearly due for some

cylinder work, let's go ahead and complete a major overhaul. In

that event, it is unlikely he will ever have to deal with anything major

on the engine again. We'll make decisions on where to send things

depending on what we see and how things measure when we tear it down.

11/18/2024 - Here's why it's in my shop. This is the engine case

just behind #1 cylinder. Note the crack coming through the case

just behind cylinder base stud. A closer examination below shows that

crack runs up the casting along behind the cylinder. This case

wasn't far from total failure. I don't think this is one DIVCO would fix.

Sorting trays all laid out to keep things organized.

It arrived with Cyl #1 already off.

I put Will Pendergrass to work tearing down the engine with some assistance and supervision on my part.

He's about got it. Not much more to do but split the case and

start measuring parts. Oh, and a few days of degreasing and bead

blasting parts.

End of the day, here's the engine stacked on 3 tables. Those big

ears on the side of the crankshaft are floating counterweights to help

smooth out the engine.

The news on the internals was a mixed bag; mostly good. The cam

and cam followers are in good used condition and will be sent to a

machine shop for regrind and hardening. The crankshaft is in good

condition, but the main journals are at minimum for new spec and the

rod journals are worn a bit beyond minimums. So, the crank will

have to go to a shop for regrinding. We will also have the crank

rebalanced. The connecting rods are going to Santa Fe to be

checked for measurements and balancing along with the wrist pins and

cylinders for honing and valve work. The cylinders appear to be

in good condition, but were not new when installed, so this is the

second run on them. We'll have to see how they measure. The

exhaust valves will likely show enough wear that it will be time to

replace them and the cylinders will need exhaust valve guides for sure.

One interesting thing I found. I don't know if someone had

attempted to replace the front seal on the engine or it had been

assembled this way, but they had used the split front seal rather than the stretched seal. That is actually an

acceptable way to install it if you have to. But, they had also

failed to install the garter spring, which is the spring that goes

inside the seal from the back to create some pressure to hold the lips

of the seal on the crankshaft. It also serves to align the seal

halves when the seal is split like this one was. Never-the-less, it

wasn't leaking a lot of oil from it. It is truly rare for me to

tear down an engine and not find something wonky inside it from the

original build.

11/19/2024 - I didn't write an update today. I simply forgot to take any pictures.

We spent all day cleaning parts and bead blasting the lead deposits out

of the cylinders. The crank, cam, and cam followers are all packaged

up and ready for Larry (the owner) to drop off at Aircraft Specialties

for machine work. The cylinders, connecting rods, and wrist pins are

all packaged up and ready to go to Santa Fe for honing, valve guides, and

valve and seat grinding, and balancing of connecting rods.

11/20/2024 - All the case parts, bolts and nuts in the left tray.

The accessories in the back tray. And all the parts for the

cylinders in the front trays. This stuff goes on the shelf while

the rest of the engine is making its way through various machine shops.

When I start building the engine, this stuff comes back out for

cleaning before installation. Note the rocker arms laying in the

trays. Yes, those are roller rockers, so roll on needle bearings

on the shafts rather than bushings and have a roller over the end of

the valve to avoid side loading the valves when they open. I

found 3 of the rotator caps that sit on top of the valves were not

rotating, so the roller rockers had worn grooves into the caps.

They will need to be replaced. I'll try to get a photo of

that before it goes back together. Also note the pushrod tube on

the far right. That's #4 exhaust pushrod. The cylinder base

nut next to it was overtorqued and I banged into the tube denting it

when the base nut popped loose. I was able to force a 5/8" dowel

rod down through the tube to push the dent out of it so the push rod

won't drag and wear a hole through the tube from the inside.

Cylinder after bead blasting.

The exhaust and intake ports after bead blasting all the lead salts out of the ports.

Inside of the cylinder heads after bead blasting.

Valves following bead blasting and cleaning with a wire wheel.

Each baggy has the valve keepers, springs, retainers and valves.

11/22/2024 - No pictures to post. We searched the local hardware

stores for the "right" shade or red paint to match the red Cardinal the

engine came off. No luck so far, so may have to go to the local

auto paint store and have them match it. The owner went to a

local paint shop and had them do a color match. Theymixed some

matching paint and put it in spray cans for him to use, then sold him

some Y2K PolyUrethane Clear Coat. It does look nice, but I'm not

enthusiastic about spraying polyurethanes in the hangar, and especially

without a respirator. Since it was a nice day, he did the paint

work outside. Yes, I have respirators, but he opted not to use

one outside.

The internal parts from this engine will be going to Aircraft

Specialties for overhaul. My gripe with Aircraft Specialties is

that they will almost always grind down a perfectly good crankshaft,

whether it needs it or not. That pads the bill for their machine

shop services, but they may also do that for liability protection.

I haven't had any problems with their finished work. When I

measured the crank on this engine, the mains measured just outside of

new limits and the rod journals measured .0015" under the limits.

Since it needs to be reground, the crank will go to Aircraft

Specialties for regrinding and balance. The camshaft and cam

followers are in good condition, so will also go to Aircraft

Specialties for overhaul.

Overhaul process for aircraft crankshafts:

Regrinding an aircraft crankshaft is significantly different from

regrinding an automotive crank. These cranks are nitrided, so are

very hard. That doesn't make a big difference to grinding, but

does affect the process as they need to go through a Nitriding process.

When the machine shop gets the crankshaft, they always dimension the

crankshafts. They measure each bearing surface in at least

two directions to check for wear. Then measure the crank

flange for runout (or wobble). The measure the center main

bearing

for runout (straightness of the crankshaft). If the crankshaft

meets minimium specs to be reground, they grind each journal to spec.

On a Lycoming, they can be ground .003, .006, .009, .010, .012, and

.015 undersized. Continental uses .010 and .020 undersize

bearings, then it's time to retire the crankshaft. The rod

journals will always be ground to the

same undersize and the main journals will always be ground to the same

undersize. But, the rods and mains may be ground to different

undersize depending on the condition of the crankshaft. I had one

recently that came back with the Mains ground .006" undersize and the

rods ground .003" undersize. One thing that is different about an

aircraft crankshaft is that there are not cut edges on a journal.

Every crankshaft I have seen has a minimum radius of 3/32 of an

inch at the edges of every journal. A sharp edge is a stress

riser and will cause the crank to fail. I've seen one aircraft

crankshaft an owner re-installed that had one rod journal that was cut

with a sharp edge. The crankshaft broke at that journal with the

crack starting at that sharp edge causing an emergency forced landing

in with the plane and proving to be very costly to the owner as the

plane was grounded 800 miles from home while an unknown shop

overhauled his engine. The shop may balance the

crankshaft at this point, but that is optional and very few crankshafts

get properly balanced. I almost always pay to have the

crankshaft balanced. Most people do not. But I love a

smooth engine. It is surprising how much they grind off a crank

to

balance them properly even though it may not necessarily have been a

rough running engine. Once balanced, the crankshaft waits for the

shop to do a weekend furnace run. The shop puts a batch of

crankshafts into a furnace where they are heated in an agitated ammonia or nitrogen atmosphere to a

temperature between 450 and 600°C. The

furnace temperature is ramped up slowly, then held at temperature for

an extended

period of time. The nitrogen reacts with the alloying elements

of the steel at the surface of the

crankshaft creating the nitrided surface that runs roughly .030" deep

into the metal. The nitrided surface is very hard and resistant

to wear and fatigue. Following the furnace run, the crankshaft

goes back to

the machine shop for pollishing. The crank is cleaned once again

and the crank journals are polished with an abrasive belt while turning

in a lathe. Once polished they are measured again for dimensions.

The crank has one last stop to make over in the plating shop.

In the plating shop, just the front of the crankshaft (flange and

front seal surface) are dipped into a vat for electro-plating with

cadmium for corrosion resistance. Once plated, the crankshaft is

ready to be shipped back for return service. You can see the

previous

cad plating on this crannkshaft in the photo above. This

crankshaft has been overhauled once before and was run a second time

with the journals polished at standard size. Now they are showing

some wear and will have to be reground to under size.

It's worth noting that this crankshaft has "free floating"

counterweights between #3 and #4 rod journals. The counterweights

are on pins and actually move around on those pins. The weights

are there to smooth the engine. If you think about it, this is a

4 cylinder engine with the same displacement as a truck engine. I

am aways amazed that they can make their horsepower as smoothly as they

do. During the overhaul process, the counterweighs are removed

and cleaned. The mounting pins may be replaced. There is

also a dowel pin at the back of the crank that is used to index the

gear that drives the accessories. That dowel pin is always

removed and replaced.

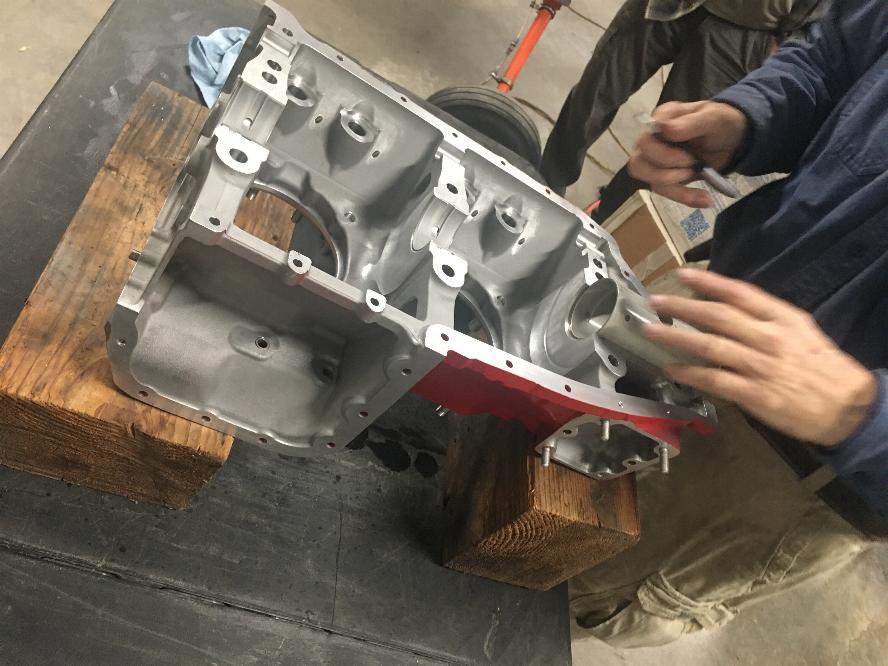

11/25/2024 - The new engine case sitting next to the old case. We

still need to move some plugs, fittings and oilers between the cases.

But gosh, isn't that new case pretty?

Masking off the new case half getting ready for paint. It should

probably be noted that any surface where a bolt seats that requires a

critical torque must be paint free. Specifically, that is where

the cylinder and case studs and throughbolts are torqued down.

Additionally, any surface you expect to seal also needs to be

paint free. That is why you see a bolt and washer covering the

holes where the bolts seat in the front collar of the case as well as

masking over the pushrod tube seats and cylinder seating area.

Painted Cardinal red to match the plane where it will be mounted.

I asked, "Why the yellow sump?" Well, 'cause it was already yellow and was easier to repaint the same color.

Masking removed. Bolts and washers were still in the front collar holes.

Case halves zip tied together for storage and the masking removed from

the case halves and accessory case. It is pretty! Now it

goes on the shelf for several weeks until we get the crank, cam, cam

followers, connecting rods, wrist pins, and cylinders back. We'll

also be ordering new pistons, rings, bearings, and all the other

associated overhaul parts once we know how far undersize the crank gets

ground.

12/3/2024 - Crank, cam and cam followers were delivered to

Aircraft Specialties today. They estimated 6 - 8 week turnaround.

If so, we'll be building this engine in February.

1/15/2025 - Parts are starting to arrive for this engine. The

crank was turned down M003, .003" undersize on both mains and rod pins.

The crank and cam followers (tappets/lifter bodies) should be

shipped this week, but I don't have them yet. The cam failed to

make spec, so a new camshaft was purchased. The valves and valve

guides all meet spec, so the valves and seats were ground and cylinders

honed. All the overhaul parts should be arriving with FedEx this

morning. I'm finishing the center section tank for the Biplane, then will get started building this engine probably the last week of January or the first week of February.

2/1/2025 - The crankshaft is here and it is a piece of art! The

first thing I do to is is take some emory cloth and scuff a helix into

the cad plated surface just behind the prop flange. The front

seal doesn't necessarily seal very well on the cad plated surface, but

scuffing a helix into it so when the engine is running the helix draws

any oil wanting to weep through the seal gets drawn back into the

engine. This trick is from a Continental service bulletin, but I

find it works quite well on both Continental and Lycoming engines.

The first order of business was to inspect the new case. I called

a halt to the build first thing as until I got more clarification.

Notice any difference between the new case above and the old case

below?

The old case has an "O" ring around every stud and through bolt that

goes through the case. Look at the upper photo of the new case

again. The center and front "through bolts" have no relief cut for

an O-ring. First I checked the parts manual. My parts

manual only calls for the small set of O-rings at the front of the case

and the larger set of O-rings around the back studs at the back main

bearing. The other two aren't shown, but it's a lousy drawing

that doesn't show the inside of the right half of the case, so is less

than clear. So, I called a friend that had recently overhauled

the exact same model engine. He sent me photos of his, which also

has a relief cut for O-rings at every stud. Is this a machining

error? Or is it a revision? I know Continental does not use

an O-ring in this position, but I've also seen a lot of case leaks on

Continentals at the through bolts. This is the beauty of having

another mechanic here on the field that has also done a lot of

overhauls. We discussed it and agreed that this is a newer

revision of the engine case and Lycoming must have decided those

O-rings were unnecessary. It doesn't make me feel warm and fuzzy,

so I'll use a bit of Hylomar and silk thread around the 4 through bolts

to ensure as best I can that they don't leak. OK, this mystery is resolved to

the best of my ability for a Saturday. On to assembling the

engine!

Later when I

installed the through bolts, I found they were an interference fit, so

the likelihood of them leaking is significantly reduced. The

through bolts were not an interfenence fit when I removed them from the

old case. If they were at one time, they weren't anymore as they

came right out with a gentle tap.

Time to get started with the assembly of this engine. At this

point in time, I have the front seal already mounted on the engine.

That front seal is not a split seal. I remove the spring

from the lip of the seal and put it back together on the

crankshaft. I boil the seal in water in the microwave, then

stretch it over the prop flange while it is warm using a selection of

tire spoons to avoid scratching the crank flange. Once it is over

the flange, it

quickly shrinks back to shape and I insert the spring into the

back of the seal. It is always a struggle to get these on, but it

always works. It took three attempts to install this seal before

I could get the leverage to stretch it over the flange. We did a

video of installing the seal, but the struggle is real and the language

may not have been appropriate for broadcasting.

At this point in time I am putting Lubriplate (TM) Assembly lube on the rod journals in preparation to install the rod bearings.

Rods are installed on the crankshaft, but the rod bolts are not

torqued. Rod bolts and nuts are always replaced on overhaul.

A torque spec on these rod bolts does not exist. You tighten

them down until the bolt stretches to meet the length specified in the

overhaul manual. In this picture, I'm using my 2 - 3" Micrometer

to measure the rod bolt length. I torqued them to 30 ft lb, then

stepped them up at 5 ft lb increments until I got the proper stretch.

In the case of this engine, that worked out to

be at exactly 50 ft. lb. on my 1/2" torque wrench to make the minimum

stretch. I had written in my manual from a previous overhaul that

it was 53 ft.lb., which would have still been within the stretch spec

for this engine.

Inserting the front bearing that takes the prop loads. This

bearing is split at the top and bottom in this picture,

or at the 90° and 270° positions when the case is sitting in

the

plane. The bearing has to be installed onto the crankshaft,

then the crankshaft carefully placed into the case while aligning the

front bearing onto the alignment dowels by feel as you can't see them

under the crankshaft. It is really easy to put them in and miss

the alignment dowels (yes, I did that on my own engine!) In order

to ensure that the bearing is

fully seated on the alignment dowels, in this photo I have the bearing

in place and am marking the sides of the bearing with a pen along the

edge of the case. When I install the crankshaft with the bearing

on it, if the lines drawn on the bearing are not fully seated to the

edge of the case, then

the bearing is not properly seated onto the dowels. If you

tighten down the case with the bearing not properly seated, you have

just damaged a very expensive bearing.

Notice the large flat area in the case just aft of the front bearing in the photo above.

That is the thrust bearing surface for this engine. Yes,

Lycoming has a machined face in front of the #1 rod throw that rides

against a machined aluminum surface in the case. That's what you

are pulling against all the time when flying behind your Lycoming

engine. That's not a critisizm as it clearly works. This

isn't a machined surface that getsfilled in and recut when a case or

crankshaft is overhauled as that would leave an unacceptable amount of

end play in the crankshaft, and there are a lot of Lycoming engines out

there with 6000 or even 8000 hours on the case that have been through

multiple overhauls.

Setting the camshaft into the right side of the case after lubricating

the camshaft bearing surfaces with assembly lube. The cam

followers are already installed under the camshaft with the faces of

the tappets lubricated with Moly/Zinc Cam break-in grease. Note

the big hole in the middle of the front saddle where the front bearing

sits. This is the oil transfer port where the prop governor

transfers oil through the front bearing into the center bore of the

crankshaft to control the prop pitch with oil pressure from the

governor. The black stuff on the face of the cam followers below

is the moly/zinc break-in grease. Each cam lobe was also coated

with this grease before the case halves were mated together.

The crankshaft is installed into the left half of the case with the

front bearing seated onto the alignment dowels. The large hole

beetween the two halves of the bearing shells aligns with the oil

transfer port in the right case half. In this photo, you

can see the oil transfer port also aligned on the crankshaft. The

bearing supports the crankshaft at the front and back of the bearing

face, and has an area between the two supports for the oil transfer

port. So, the crankshaft is completely surrounded with

pressurized oil inside

the bearing shell so oil transfers to the prop all the time, not just

when the port aligns with the hole in the bearing. The prop

governor is regulating the pressure at that hole in the front bearing

and can run as high as 410 psi. That is why the oil transfer line

and fittings from the governor to the prop hub are required to be steel

or stainless steel.

Painting the left side of the case with Hylomar Blue sealer. That little bottle of sealer is about $100.

Laying silk thread into the sealing surface of the left half of the

case. You can see in the background that I have both surfaces

painted with a thin coat of Hylomar. The manual only calls for

coating one surface, but I find that I get no leaks with this method.

I'm putting a bit of silicone sealant on the outer flange of the front

seal, then will push the seal into place. This is the only place

silicone sealant should ever be used in an aircraft engine.

The left half of the case has been mated to the right half of the case.

Note the little pieces of safety wire tied around a couple of

cylinder base studs. That is some .020" safety wire that is

wrapped around the camshaft to hold it into the right case half while

lowering the right half down onto the left half. With the cam

trapped into it's bearing blocks, it also holds the cam followers captive

into the right half of the case. You can gently lower the right

half of the case onto the left half without having all the parts

falling out. Once in place, you snip the safety wire and pull it

out.

Also note above that the through bolts are not installed yet.

That's why there are two studs missing at the front of #1 and #3

cylinders on the case.

The engine goes onto the stand for further assembly. Note that

the through bolts are in the case at this point in time. We

polished the heck out of the bolts and still found them to be a quite

snug interference fit. They had to be driven in with brass drift

and 2# hammer. It would be kinder for the through bolts if I did this with a lead hammer... if I owned one.

Fuel divider and a few other goodies getting installed onto the case.

Oil temp thermocouple is screwed into the front of this case.

The case bolts are all torqued in and the 3 internal bolts safety wired.

And that pesky castilated case nut that's hidden under the cam gear.

Lots of people tell me about building a special wrench to get to

that nut. You can actually get to it with a tool common to every

aircraft mechanic's tool set. The 9/16" cylinder base wrench will

do it. That little bit of scoring under the nut was my action

with a punch trying to get at the cotter key to bend the tangs on it

properly.

The cylinders are all painted and ready for installation on Monday.

That's going to smell funny on the first run of this engine!

2/5/2025 - Installed all the cylinders. This particular engine

has roller rocker arms installed on it. I've never seen them in a

Lycoming engine before, so have to look for an adverse effects or wear

caused by them. The back two cylinders don't have the rockers installed. The explanation is below.

And there it is. The valve rotator caps rather than rotating as

they should under a standard rocker arm, have a groove worn into them

from the roller on the rocker arm. I had spotted the top three previously

and had new caps ordered to replace them. But upon closer

inspection this morning, I found three more than were showing a small

amount of wear that was only visible when light was reflected against

the top surface. I put the assembly on hold and ordered more

replacement rotator caps. They should be here on Thursday.

This is the roller rocker arm used in this engine. While it

caused some wear issues with the valve rotator caps, the concept of

roller rockers clearly works. This engine had 1000 hours since it

was last overhauled. The valves and valve guides, including the

exhaust guides, still met new spec and did not require replacement.

I have never seen a Lycoming or Continental engine that didn't

need new exhaust valve guides by 1000 hours. This one did not.

These are kind of a bugger to install with needle bearings and

thrust bushing both inside and on the side of the rocker arms.

While waiting for the valve components to arrive, I decided to assemble

the gear train in the accessory case instead. This was a test

assembly, then the gears were removed and cleaned, then reassembled and

packed with assembly lube before installing the accessory case.

In order from the top to bottom, the gears are Camshaft, Cam

idler gear, to the left is the magneto drive gear/coupling, and below

that is the idler gear that drives the prop governor. The gear

that is laying on it's side is the vacuum pump drive gear. The

oil pump drive and prop governor drive are missing as they are

installed in the accessory case. The vacuum pump gear will also

be installed in the accessory case before the accessory case gets

installed onto the engine. The long shaft that is sticking out of

the cam gear below is the tachometer drive shaft. It sticks out

through the accessory case through a bushing and seal where the

tach cable gets plugged into the end of the tach drive shaft and

screwed onto the tach drive on the back of the accessory case.

This engine was part of Lycomings "76" series engines, designed

to be simpler and less expensive than the previous engines. They

were neither. However, they used a single drive dual magneto,

which turned out to be a terrible idea and created a single point of

failure for the ignition systems. They are reliable, but have now

been disowned and new production ceased by Bendix, the owner of this

magneto design. Now you can only get them repaired, but not

replaced. We considered changing this engine to the more standard

dual magneto setup during overhaul, especially since we were replacing

the engine case. But the cost of a different accessory case and

all the internal drive gears was prohibitively high.

Gears in place, on the back of the engine. The gear seating

lubricated for gears in the accessory case to seat into. The

gasket is in place and painted with Hylomar. Below, the oil pump

is assembled, packed with assembly lube and bolted into the accesory

case. The vacuum pump drive gear is installed at the top and the

prop governor drive gear is installed at the bottom. The fuel

pump push rod is in place in the sleeve in the center or the accessory

case. It rides on the eccentric cam that is built into the

camshaft idler gear above.

Accessory case is installed with the gears well lubricated with assembly lube. This is a look up inside from the bottom.

Accessory case installed and torqued down.

This is the ball and spring that goes inside the oil pressure

regulator. In this model, you remove the regulator and add a

washer behind the spring to increase the default oil pressure.

There is another model avilable that you can just turn an

adjustment bolt in to tighten the spring and raise the oil pressure.

The two models are interchangeable.

The oil pressure regulator screws into the case just behind #3 cylinder, then gets safetied into place.

Oil filter canister, fuel pump and

prop governor installed.

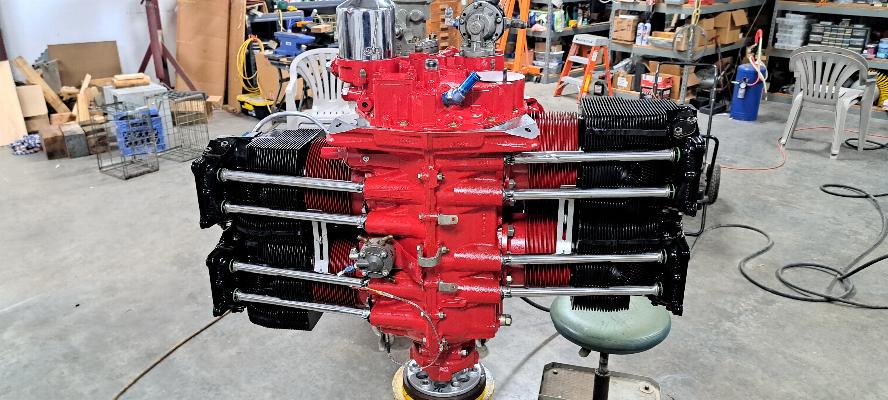

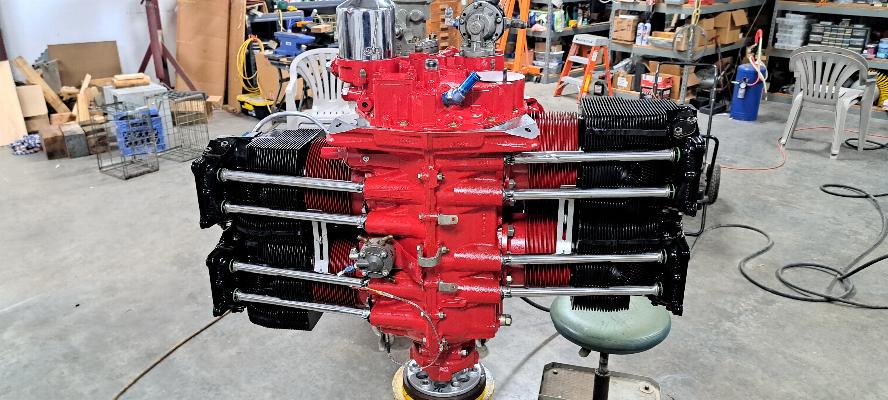

2/7/2025 - After a week of FedEx Ground losing parts and shipping them

to the wrong end of the country, Air Power overnighted us the

replacement parts. Yes those three little rotator caps from a few pictures up have held us at a standstill all week. This

afternoon we could finally get back to work. Now the cylinders are

mounted and the intercylinder cooling baffles are installed.

A word about Air Power for parts. Their prices are lowest I can

find. There is no tax on the parts. And Fed Ex Ground

shipping is free. Overall, I save about 25% by buying my

Luycoming (Superior) and Continental parts through them. The

fiasco this week was not their fault, but the ineptitude at FedEx

ground. Air Power overnighted me a second set of parts at no

charge and will settle up with me once FedEx actually finds and

delivers the parts that were supposed to be here two days ago, then

they will have them shipped back to them. Now that is service,

and I am very pleased with them.

Intercylinder baffles shown from below. These force air around

the bottom of the cylinders and cylinder heads to help them cool.

Also, the oil drains for the cylinder heads are now installed.

The fuel injectors are installed into the heads and fuel injection

lines are on, with my disassembly labels still hanging on them I

still need to put all the adel clamps onto the injector lines to

support them.

Oil tank and intake runners are now installed.

Fuel injector line supports are in place now. There are still a

few more things to go back onto this, but I hope to complete this

engine tomorrow and get it loaded into the shipping crate to head back

home.

2/8/2025 - Fuel servo and all the plumbing installed. The engine is complete and time to clean up the shop.

Engine is on the hoist and headed into it's crate for the trip back to Oregon. Bye, bye...