The RV-6 Rebuild project

Page 2

February

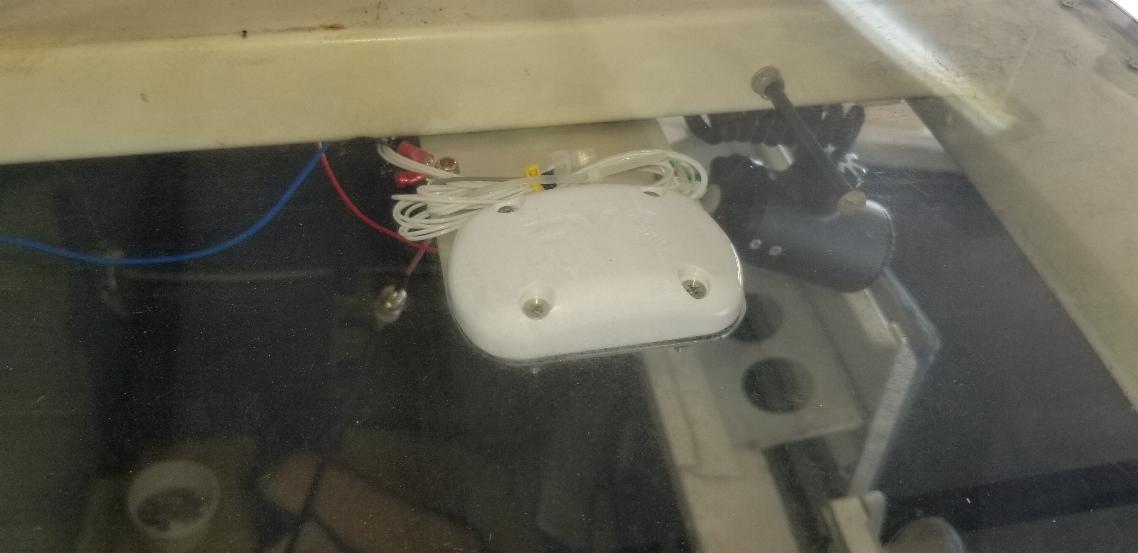

2020 - I ran across this RV-6 in Albuquerque, NM. It has been

damaged, but was priced about right, so I bought it. Not sure if

it was the right thing to do or not, but now I'm committed. At

first glance, it doesn't look too bad. But then there are all the

things I didn't know that I had to learn before I moved it.

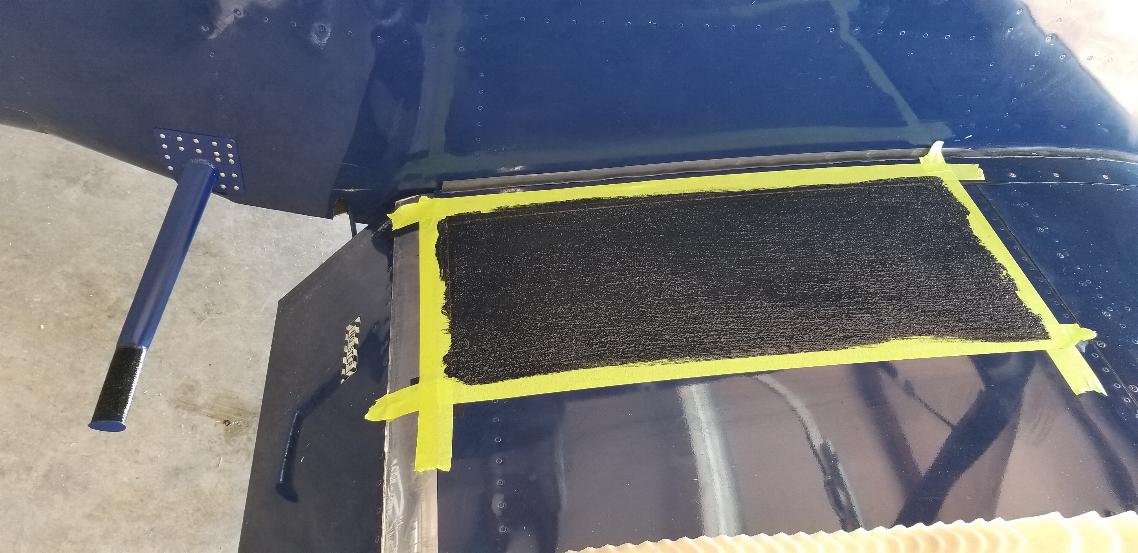

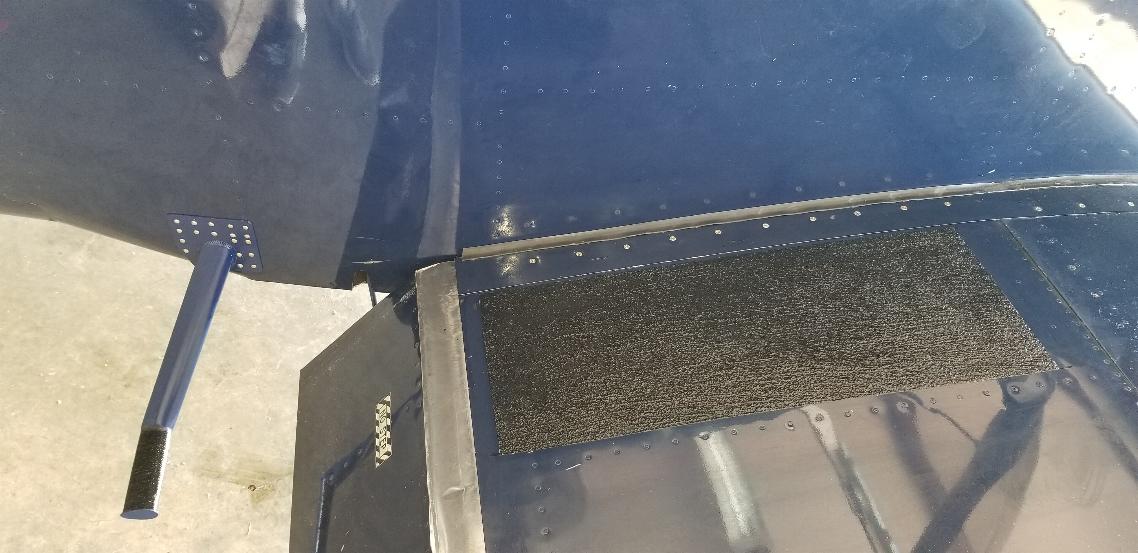

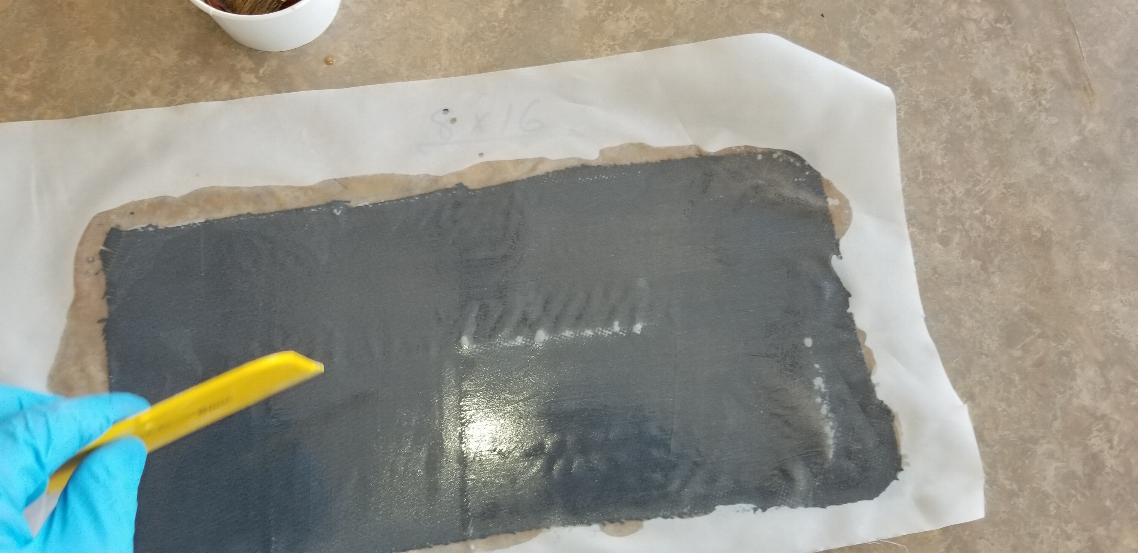

Painting is a lot like playing golf. On occasion you have a

good day, but you never get it right. But your bad days are there

to show forever with paint work.

Painting is a lot like playing golf. On occasion you have a

good day, but you never get it right. But your bad days are there

to show forever with paint work.