December 2008

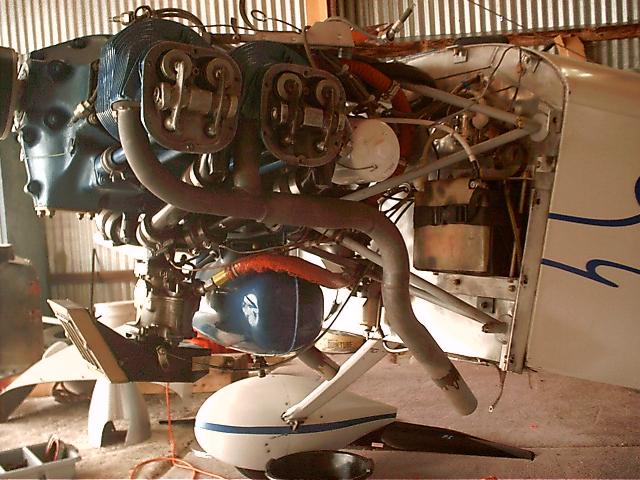

In October of 2008 I decided to tear

down my engine to replace the worn valve guides that I didn't replace

when I originally built up this engine. While it was down, we

found some issues from running the high compression (8.7:1 vs 7.0:1)

C-85 pistons that caused me to decide to downgrade the engine back to a

stock O-200. With the plane being down for a several weeks, I

decided this would be a good opportunity to build the new exhaust I've

been promising myself for several years. Additionally, with the

lower compression pistons, I hope to regain some of the lost horsepower

by building a much better breathing exhaust system.

All of the papers I have read say that the small Continentals don't

have enough valve overlap in the cam to take advantage of the

scavenging of a crossover exhaust system. Consequently, I decided

to make life a bit easier for myself by welding up 4 separate headers

using 1 1/2" mild steel pipes from the local muffler shop. Yeah,

I know they are heavy, but I can weld them with my torch and custom

build the whole unit in my hangar. I visited a low budget muffler

shop and had them bend up two 7' sticks of 1 1/2" tubing with a

total of 8 - 90 degree bends and 4 - 45 degree bends. I

bought a set of mild steel flanges from Aircraft Spruce, then

simply cut the pieces of pipe and welded them back together to build my

custom exhaust. Total cost , $100.